Industrial Water Resource Utilization and Zero Discharge Technology

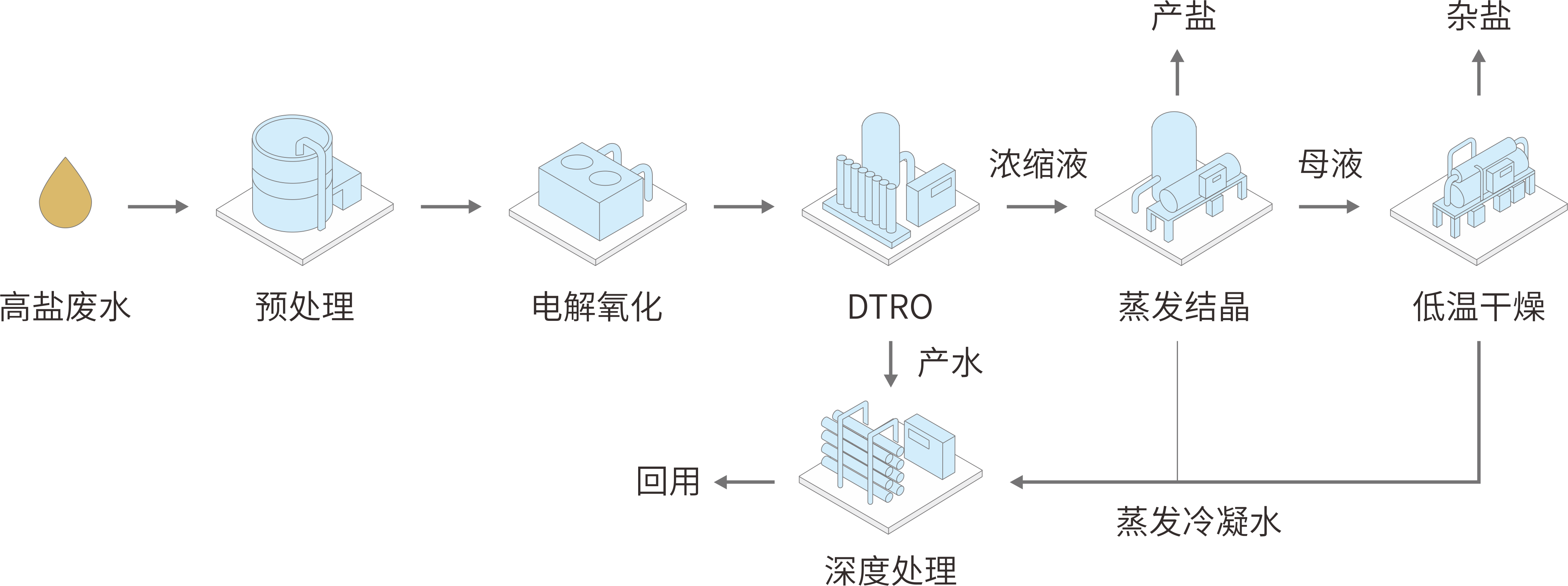

Process 1

This process can remove most organic matter from high-salt wastewater through pretreatment and electrolytic advanced oxidation, ensuring the quality of salt produced from zero discharge. Meanwhile, it reduces the scale of the evaporation and crystallization unit via DTRO concentration and volume reduction, significantly lowering the wastewater treatment operating cost.

Application Fields

Zero discharge of high-salt and high-organic-matter wastewater

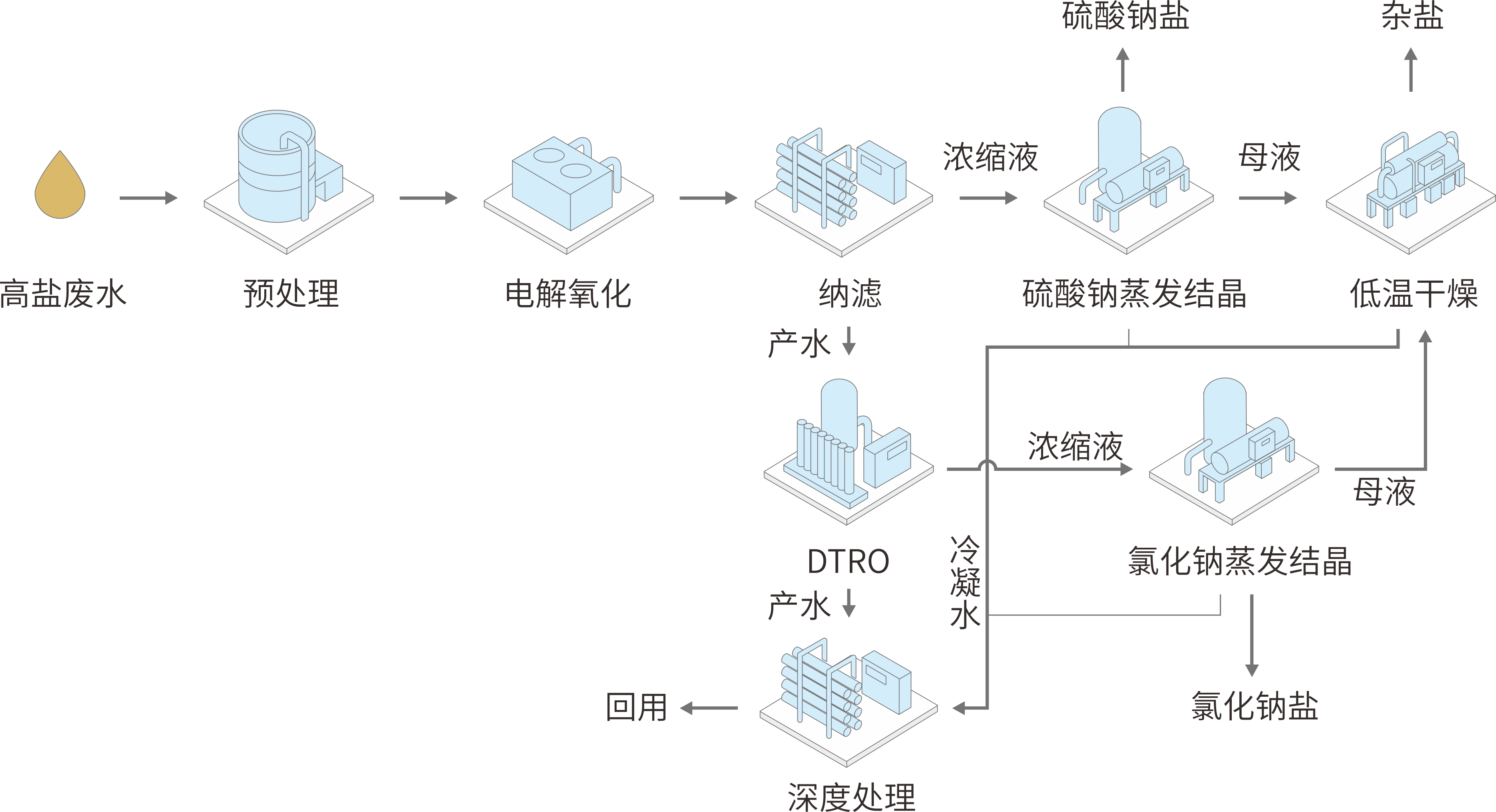

Process 2

This process can remove most organic matter from high-salt wastewater through pretreatment and electrolytic advanced oxidation, ensuring the quality of salt produced in zero discharge systems. Via the efficient separation of sodium sulfate and sodium chloride by DTNF, it realizes the recovery of sodium sulfate and sodium chloride, thereby achieving wastewater resource utilization.

Working Principle Diagram

Application Fields

Zero discharge of wastewater with high chlorine, low sulfate and high organic matter.

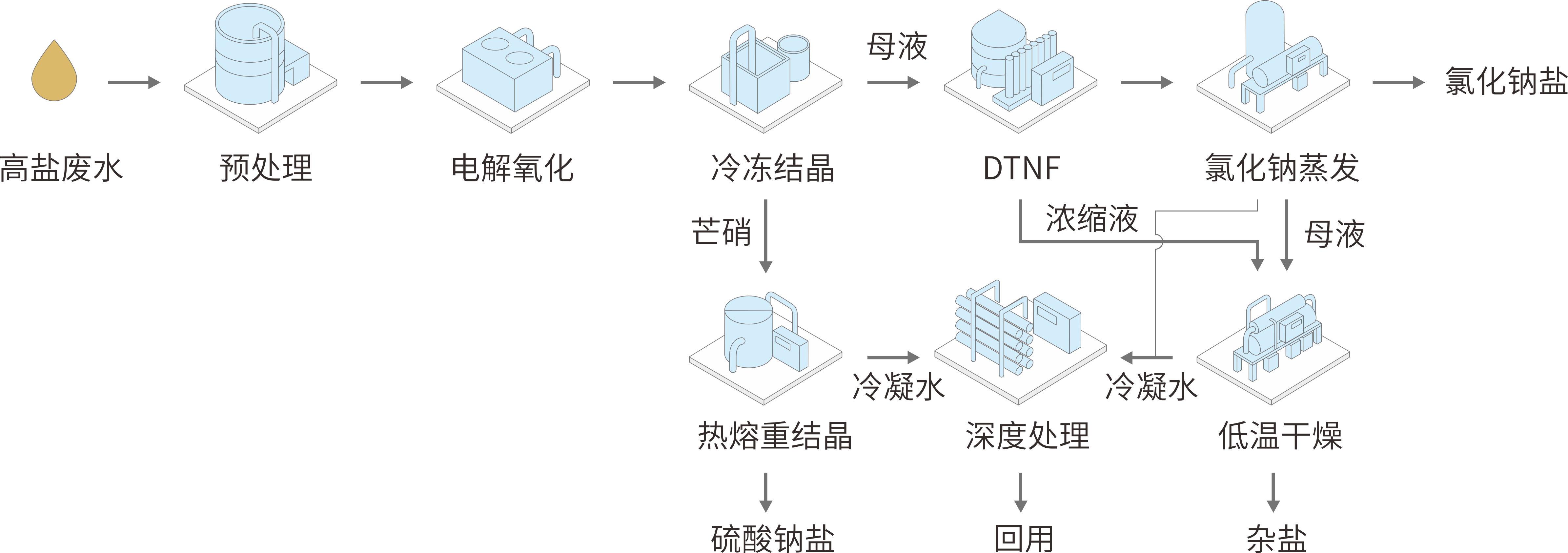

Process 3

This process can remove most organic matter from high-salt wastewater through pretreatment and electrolytic advanced oxidation, ensuring the quality of salt produced in zero discharge systems. Via the efficient separation of sodium sulfate and sodium chloride by freeze crystallization + DTNF, it realizes the recovery of sodium sulfate and sodium chloride, thereby achieving wastewater resource utilization.

Working Principle Diagram

Application Fields

Zero discharge of wastewater with high chlorine, high sulfate and high organic matter.

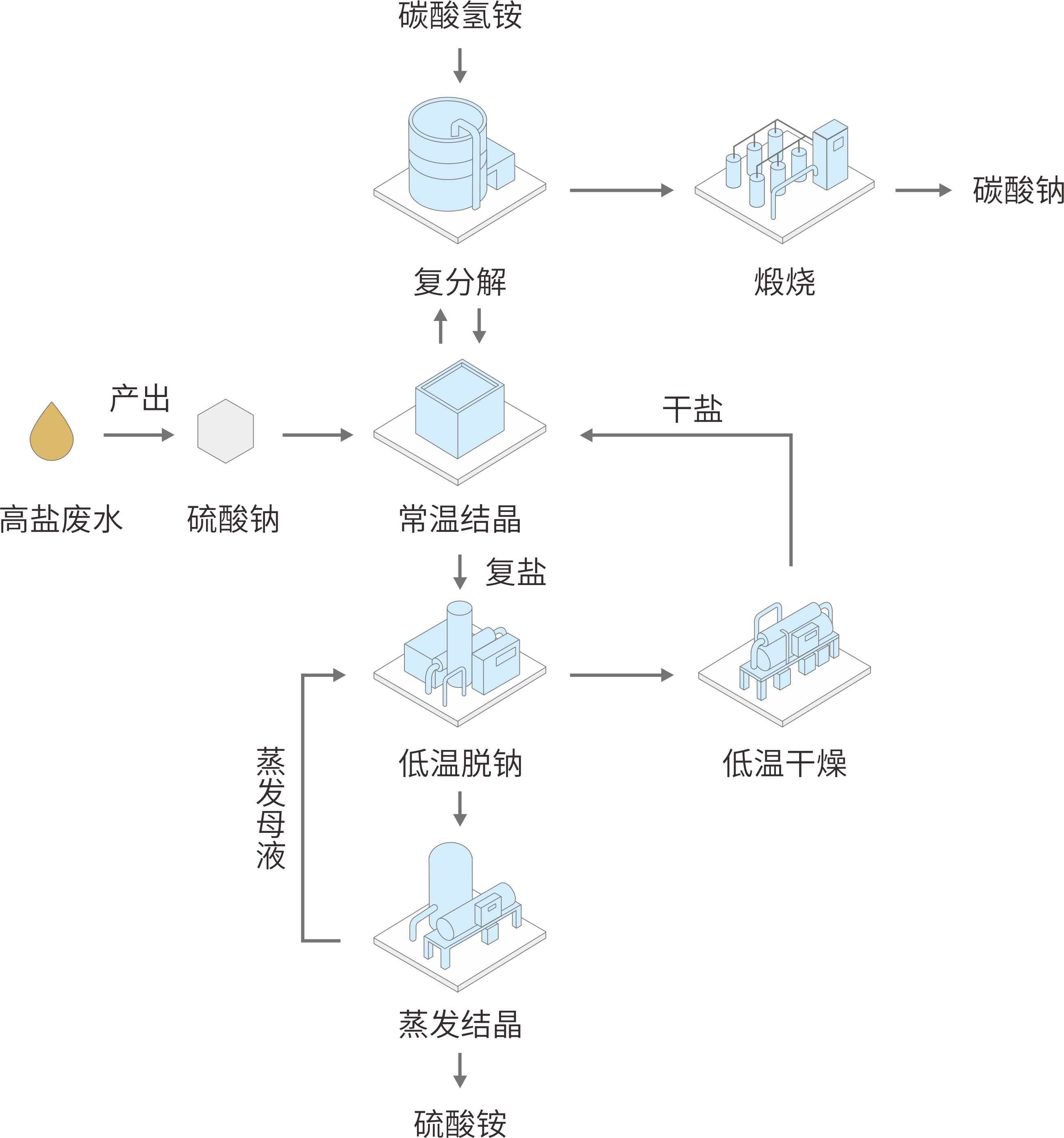

Process 4

This process realizes the deep resource utilization of sodium sulfate produced from high-salt wastewater. By adding ammonium bicarbonate, through processes such as crystallization, metathesis reaction and evaporation, low-value sodium sulfate is converted into high-value sodium carbonate and ammonium sulfate, further reducing the treatment cost of high-salt wastewater.

Working Principle Diagram

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115