Near-Zero Discharge of Oil and Gas Field Produced Water

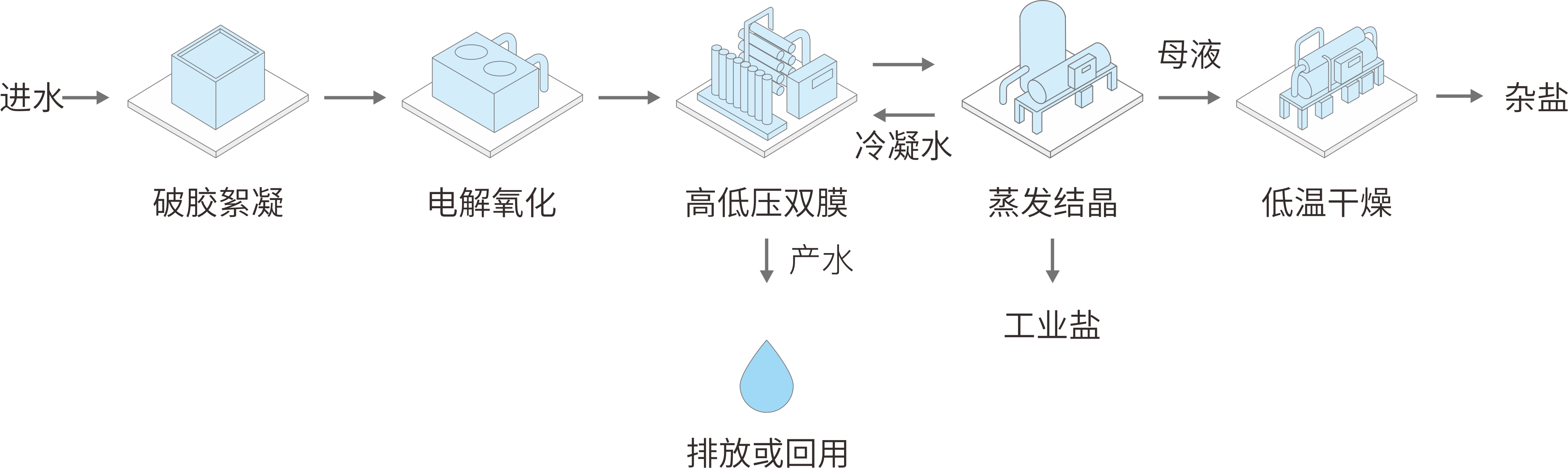

This technology is a near-zero discharge technology independently developed by the company for oil and gas field produced water treatment. It consists of the processes of "gel breaking and coagulation + electrolytic oxidation + high-low pressure dual membrane + MVR + low-temperature drying".

Main Features:

Main Features:

Scope of Application:

Shale gas produced water, fracturing flowback fluid and other scenarios in the oil and gas field industry

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115