Help the petroleum and petrochemical industry

From: This site Time: 2023.10.17 View:

From October 12to13, the "2023 Annual Meeting of National Water Injection and Water Treatment Technology Center Station" sponsored by Sinopec Petroleum Engineering Design Co., Ltd. was held in Chengdu Century City. The theme of this conference is "Green driving, low-carbon leading, promoting the high-quality development of petroleum and petrochemical 'water' system", focusing on the future development of technology in the field of water treatment in the petroleum and petrochemical industry.

△Photo of participants

Chengdu SOTEC Technology Co., Ltd. was invited to participate in the meeting, and Huang Xingjun, deputy general manager of Shuote Technology, gave a speech entitled "Gas Field Water Resource treatment Technology". In the speech, Huang shared the status quo of gas field water treatment, core technology of Shuote Technology, technology package of Shuote gas field water resource treatment technology, application cases and other contents to the leaders and representatives of the participants. It further demonstrated the technical strength and R&D innovation capability of Shuote Technology in the field of gas field water resource treatment, and deepened the exchanges and cooperation with the participants.

△Deputy General manager Huang Xingjun speech

With the rapid development of national economy, the oil demand continues to expand, the rapid growth of natural gas production, the majority of oil and gas development workers in order to ensure the stable supply of domestic oil and gas fields to study oil and gas field development technology. Therefore, the optimization and development of upstream mining technology has resulted in the continuous increase of the water pollution index coefficient of the gas field. The organic matter composition is complex, difficult to degrade, high concentration, high salt, high COD and high ammonia nitrogen, and the deep brine will be brought out during the mining process, making the produced water contain lithium, and the added value will be generated in the subsequent recycling process. Therefore, the oil and gas field wastewater treatment technology can not fully meet the current wastewater treatment index requirements.

In view of the difficulties in this industry, Shuote Technology launched the gas field water resources treatment technology through independent research and development - "pretreatment + concentration reduction + resource recovery", the process technology has "three characteristics, three innovations, three resources".

01. Three technical features

1. No need to remove the hard pretreatment;

2. All equipment is modular;

3. Similar operating costs are low.

02. Three innovative devices

Core technology

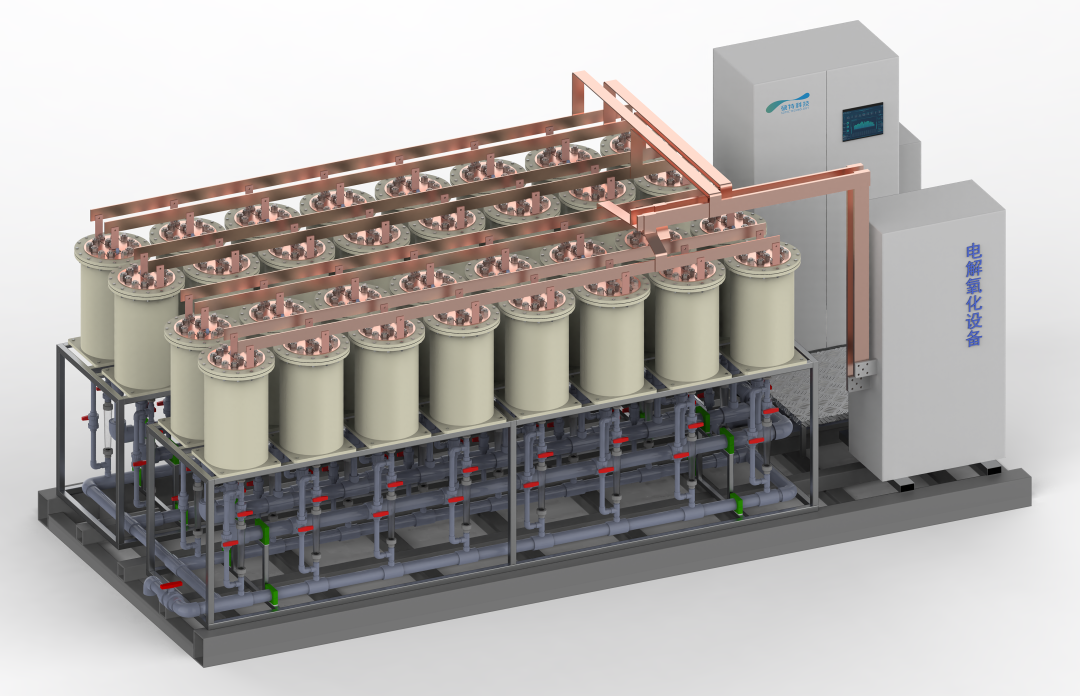

Electrolytic oxidation equipment

1. Electrolytic oxidation equipment: synchronous and efficient removal of organic matter and ammonia nitrogen in water.

2. Lithium extraction process package: Extract lithium from the most complex water body to realize the resource utilization of lithium carbonate.

3. Ultra-low temperature drying equipment: thoroughly treat nanofiltration concentrated water, reduce energy consumption, reduce hazardous waste.

03. Three resource recycling

1. Water: High quality produced water to the park for reuse.

2. Lithium: Lithium extraction reaches industrial grade lithium carbonate products.

3. Salt: Sodium chloride reaches industrial grade products to remove chlor-alkali chemical plants.

(1) Efficient removal of COD and ammonia nitrogen at the same time: the free radicals generated in the reaction process can react directly with organic pollutants in wastewater without selection, degrading them to CO₂, H₂O and simple low molecular organic matter; At the same time, it can react with ammonia nitrogen in water and degrade it quickly.

(2) Suitable for high salt wastewater system: it is not limited to all kinds of salt composition and concentration.

(3) Green clean advanced oxidation technology: electron transfer is only carried out between the electrode and the waste water components, no drug, no sludge, no secondary pollution.

(4) Titanium anode material has high stability and long service life: acid resistance, alkali resistance, high potential resistance and other corrosion resistance.

(5) Modular design, high integration.

Ultra-low temperature drying equipment

(1) The reduction effect is good: the reduction is more than 80%, and the evaporation residue moisture content is lower than 15%.

(2) Relatively low energy consumption: low temperature operation (about 37-45 ° C), less steam consumption, small heating power.

(3) Stable operation, not easy to scale: the use of self-developed scraper structure (patent number: ZL202210914069.X).

(4) The condensate water quality is good: in the high vacuum (-80 ~ -90kPa), ultra-low temperature (about 37-45℃) environment operation, the boiling point of the liquid is reduced, the water is volatile, and the concentration of pollutants such as COD and ammonia nitrogen in the condensate is low.

(5) High degree of automation: one-click operation, background real-time monitoring.

(6) Modular design, high integration.

(7) Intake water quality: no special requirements.

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115