50m³/h! The electrolytic oxidation device of gas field resource water treatment project has been shipped

From: This site Time: 2023.10.31 View:

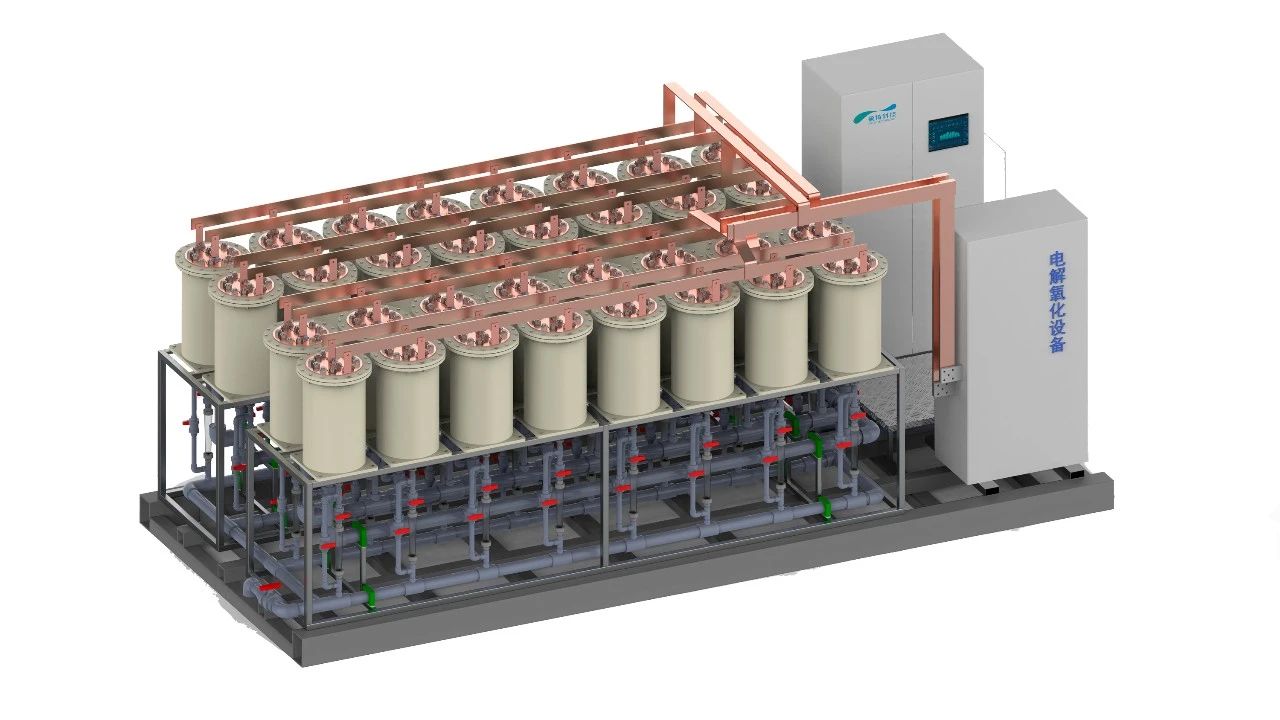

On October 29, six large trucks loaded with equipment at the gate of Shuote Technology factory were ready to go. The batch of equipment consists of 6 sets of electrolytic oxidation equipment and supporting facilities, which will be sent to the resource water treatment system expansion project site of Yuanba gas field, Gas Production Plant No. 2 of Sinopec Southwest Oil and Gas Company.

From the signing of the project to the smooth delivery, Shuote Technology gives full play to its own advantages, and actively integrates high-quality resources. During the production period, all departments cooperate with the production center, and the production center focuses on efficiency, quality control, speed improvement, ensuring smooth operation of production, delivering products to the owner on time according to quality and quantity, and fully ensuring the smooth delivery of each piece of equipment. Meet the owner's production needs.

Equipment delivery

On the same day, the batch of equipment has successfully arrived at the receiving place designated by the owner, and Sotec Technology will continue to complete the follow-up on-site installation and commissioning work to ensure the smooth operation of the equipment.

Project profile

Project profile

01、Project name: Resource water treatment system expansion project of Yuanba gas Field, No. 2 Gas Production Plant of Sinopec Southwest Oil and Gas Company

02、Equipment supply: 6 electrolytic oxidation devices and supporting facilities

03、Design scale: 50m³/h

04、Project location: Daping Village, Zhongtu Town, Cangxi County, Guangyuan City, Sichuan Province

Electrolytic oxidation equipment

Equipment description: Electrolytic oxidation equipment is an efficient integrated skid-mounted equipment independently developed by Shuote Technology. It is an electrochemical oxidation equipment that can remove organic matter and ammonia nitrogen at the same time. The equipment adopts titanium composite anode material and special reactor structure design, strong acid and alkali resistance and high potential corrosion resistance, long service life of the equipment, suitable for all kinds of high salt and high COD organic wastewater decarbonization treatment, but also suitable for high salt ammonia wastewater deammonia treatment.

Equipment advantages:

(1) Efficient removal of COD and ammonia nitrogen at the same time: the free radicals generated in the reaction process can react directly with organic pollutants in wastewater without selection, degrading them to CO₂, H₂O and simple low molecular organic matter; At the same time, it can react with ammonia nitrogen in water and degrade it quickly.

(2) Suitable for high salt wastewater system: it is not limited to all kinds of salt composition and concentration.

(3) Green clean advanced oxidation technology: electron transfer is only carried out between the electrode and the waste water components, no drug, no sludge, no secondary pollution.

(4) Titanium anode material has high stability and long service life: acid resistance, alkali resistance, high potential resistance and other corrosion resistance.

(5) Modular design, high integration.

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115