How can the wastewater treatment industry become carbon neutral?

From: This site Time: 2022.07.25 View:

How can the wastewater treatment industry become carbon neutral?

Global warming is becoming more and more intense, the main reason is the large amount of greenhouse gas carbon dioxide emissions. Therefore, low-carbon production and life are imperative, so in recent years, many scholars put forward the concept of carbon neutrality. In the process of sewage treatment, the COD in sewage is consumed by microorganisms, but the greenhouse gas carbon dioxide is produced and discharged into the air. At the same time, the power consumption in the process of aeration also produces a lot of greenhouse gases. Water pollution is solved but it is transferred into the air. It is roughly estimated that in 2030, the greenhouse gas emissions of China's entire sewage treatment industry will reach 2.95% of the national greenhouse gas emissions. Therefore, it is imperative for the sewage treatment industry to change its direction to achieve low-carbon or even zero-carbon sewage treatment.

One,Carbon neutralization in sewage treatment process

Sewage is actually a carrier of resources and energy. It contains a lot of organic matter, which is a kind of energetic substance, and also contains a lot of phytonutrients (nitrogen, phosphorus and potassium). The essence of sewage treatment is a complex process of separating, degrading and transforming pollutants in sewage (mostly organic pollutants) through artificial complicated technical means, at the expense of resources and energy. In other words, sewage treatment is an energy-consuming carbon emission process, or a gradual evolution from water pollution to air pollution. The traditional sewage treatment means is to use bacteria to metabolize organic matter in sewage. In order to improve the work efficiency, a lot of power is needed to aerate and increase the DO (dissolved oxygen) in water. In this process, bacteria metabolism will produce a lot of CO2, and a lot of CO2 will be produced to provide the power used for aeration.

What are the offsets?

The first is energy consumption, mainly electricity consumption. From the perspective of energy conversion, the essence of traditional sewage treatment mode is energy consumption for water quality. We use a lot of electricity to remove pollutants from sewage, which indirectly produces a lot of carbon dioxide emissions. Second, sewage treatment needs to consume a lot of fuel and pharmaceutical, indirect emissions of a large number of greenhouse gases. In addition, the aerobic stage needs aeration, and a large amount of aeration requires high-power blowers to provide high air volume, and its process power consumption is high.

Through continuous technological innovation, Shuote environmental protection mainly realizes carbon neutrality through energy conservation, emission reduction, resource reuse and other ways.

Two, Shuote environmental protection treatment technology

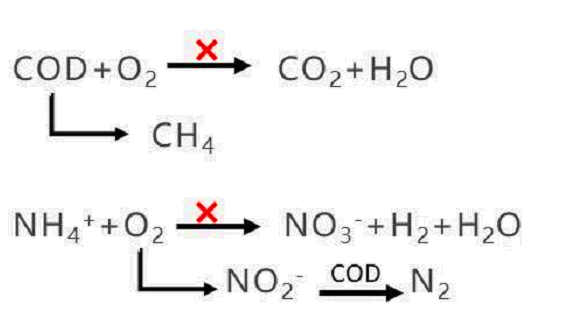

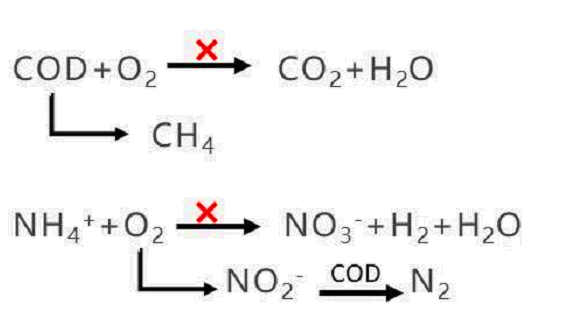

As shown in the above formula, organic matter COD was oxidized to CO2 directly in this "energy dissipation" way to remove, not as much as possible into renewable energy substances such as CH4 and achieve carbon neutral, so that it can greatly reduce the consumption of external energy (fossil fuels), reducing power and indirect carbon emissions.

1.Anaerobic treatment technology

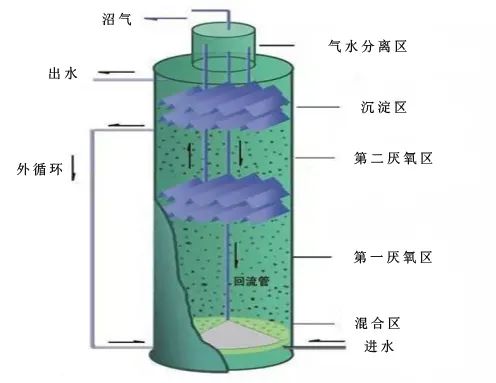

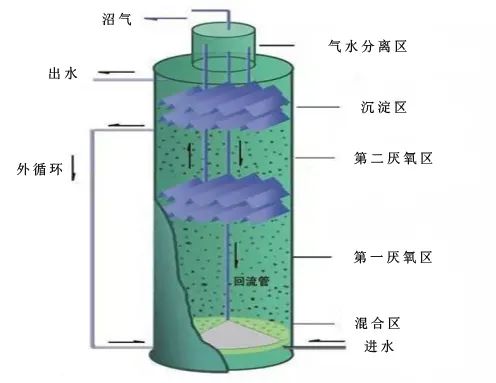

The sewage first enters the mixing zone at the bottom of the anaerobic reactor, and fully mixes with the internal circulating mud-water mixture from the reflux pipe, and then enters the first reaction chamber for biochemical degradation of pollutants. The COD volume load here is very high, and most influent COD is degraded here, and a large amount of biogas is produced. Biogas is collected by a lower three-phase separator and rises up the reflux line. As the biogas rises, the mixture in the first reaction chamber is lifted to the gas-liquid separator at the top of the IC anaerobic reactor, where the biogas is separated from the sludge and discharged to the reactor. The slurry mixture is returned to the bottom of the reactor along the reflux pipe, and is fully mixed with the influent into the first reaction chamber, forming an internal circulation. The sewage treated by the first reaction chamber will automatically enter the second reaction chamber for further treatment. The biogas generated is collected by the gas collecting hood in the second reaction chamber and enters the gas-water separator through the riser. The mixed liquid in the second reaction chamber is separated by solid and liquid in the precipitation area, the treated supernatant is discharged by the outlet pipe, and the precipitated sludge can be automatically returned to the second reaction chamber.

The main component of anaerobic biogas is methane. Methane is the cleanest energy substance. Biogas can be used as energy after purification, so that the organic pollutants in the water are eventually converted into electricity, which not only reduces the consumption of external energy (fossil fuels). And it avoids converting organic matter into carbon dioxide and releasing it into the atmosphere.

2.Short-cut nitrification and denitrification process technology

1)Fundamentals Traditional biological denitrification process requires two complete nitrification and denitrification process, and the shortcut nitrification and denitrification is to control the nitration process of ammonia nitrogen and nitrate nitrogen, abundant accumulation of nitrate in the system, and then under certain conditions, the system of denitrifying bacteria in organic substrate as electron donor, will the nitrate reduction of nitrogen, Thus achieve the goal of nitrogen removal. The reaction equations are shown in Equations (1-1) and (1-2) :

Nitrosation:NH4+−N + 1.5O2 → NO2‾−N + H+ + H2O (1-1)

Denitrification:6NO2‾−N + 3CH3OH + 3CO2 → 3N2 + 6HCO3‾ + 3H2O (1-2)

Traditional biological denitrification process requires two complete nitrification and denitrification process, and the shortcut nitrification and denitrification is to control the nitration process of ammonia nitrogen and nitrate nitrogen, abundant accumulation of nitrate in the system, and then under certain conditions, the system of denitrifying bacteria in organic substrate as electron donor, will the nitrate reduction of nitrogen, Thus achieve the goal of nitrogen removal. The reaction equations are shown in Equations (1-1) and (1-2) :

Nitrosation:NH4+−N + 1.5O2 → NO2‾−N + H+ + H2O (1-1)

Denitrification:6NO2‾−N + 3CH3OH + 3CO2 → 3N2 + 6HCO3‾ + 3H2O (1-2)

According to the above formula, short-cut nitrification and denitrification is based on NH4+−N→NO2‾−N→N2

2)Technical featuresThe contribution of this technology to carbon neutrality is mainly as follows:

1. Reduce energy consumption. Data show that the power consumption per ton of water in China's sewage treatment plants is generally in the range of 0.15 ~ 0.28kWh. Among them, the power consumption of aerated blower accounts for 56.2%. Although the energy consumption of different treatment processes is different, it is a fact that the total energy consumption of the aeration system is the largest. Therefore, the key point of energy saving and consumption reduction in sewage treatment process is to upgrade the aeration system. Aeration system is mainly to provide dissolved oxygen needed by microorganisms, so the core of energy saving is to accurately control the growth process of microorganisms, to prevent excessive aeration, but also to prevent insufficient aeration. The water consumption per ton is greatly reduced compared with the traditional process. In the process of short-cut nitrification, the oxidation of NH4+-N is controlled at the stage of NO2‾-N, in which the dissolved oxygen is low. The dissolved oxygen of ordinary AO process is ≥2mg/L. Our company will control the dissolved oxygen within 1mg/L, reduce the energy consumption of the fan by about 50%, and obviously save the operation cost.

2. Reuse of energy. In the denitrification process, NO2‾ -n is directly reduced to nitrogen, the required organic carbon source is lower than NO3‾-N reduction nitrogen, the C/N consumed by this technology is about 2.5, and the conventional nitrification and denitrification C/N needs to be greater than 4, at least can save more than 30% of the carbon source, saving this part of the carbon source can be used for the front-end anaerobic system to produce biogas, used for power generation, To realize "turning waste into treasure" and avoid consuming a lot of carbon source in biochemical process.

3. Carbon reduction. After sewage treatment by biochemical process, part of the organic matter in the water under the action of microorganisms, generated their own cell material and sludge, sludge landfill, so as to avoid this part of the organic matter into carbon dioxide emissions into the atmosphere, to achieve the purpose of carbon neutrality.

Three. Actual cases of leachate treatment in Central China

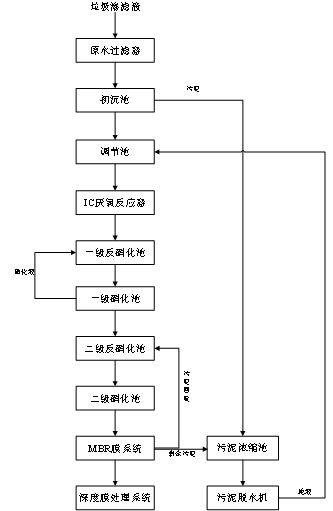

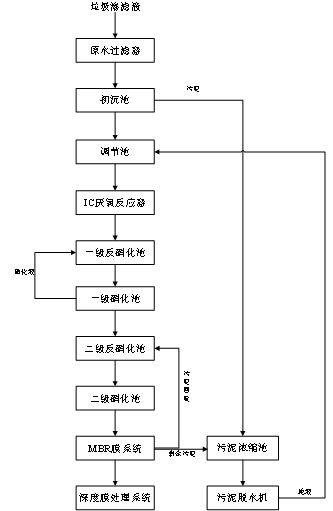

1. Process flow chart

2. Process description

1) Anaerobic nitrification: the leachate can produce biological gas (biogas) through anaerobic nitrification. The main component of biogas produced by anaerobic nitrification is methane. The renewable energy produced by anaerobic nitrification is CH4, which can be incinerated for power generation, so as to achieve carbon neutrality.

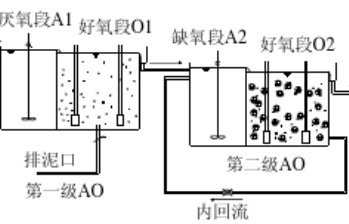

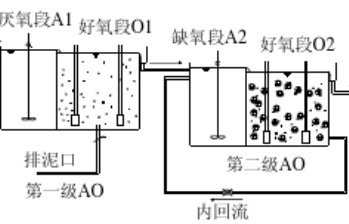

2) Biological treatment: two-stage AO process, stage A is full adsorption and transformation of organic matter in the raw sewage, nitrogen and phosphorus will also be significantly reduced due to bacterial synthesis or chemical precipitation; In the O section, organic matter in sewage is removed by biological degradation in the aeration tank. Ordinary NH4+ is oxidized to NO3- through nitrification, and NO3- is removed by denitrification to generate N2. The dissolved oxygen in this process is ≥2mg/L.

3) Sludge concentration: in the AO section of the surplus sludge, first of all to concentrate the sludge, reduce the volume of the surplus sludge.

4) to save carbon source, making full use of leachate in the BOD carbon source for denitrification, and improve the efficiency of energy recovery, reducing the consumption of chemicals with maximum extent, in a broader sense to reduce the whole social resource and energy consumption, and reduce the introduction of chemicals in sewage treatment plant effluent, the mud of the environmental risk.

Four. Future factory

The future is not to transform the sewage treatment station/plant into a single nutrient, energy or reclaimed water plant, but to explore the potential of sewage resources/energy as much as possible, and realize the nutrient, energy and reclaimed water production plant in the same sewage treatment station/plant (NEWs).

So far, there have been some successful practices at home and abroad, and we have reason to believe that China's wastewater treatment industry will soon make a positive contribution to the carbon neutrality strategy. Shuote Environmental Protection will carry out the carbon emission reduction work systematically and comprehensively, follow the national "14th Five-Year Plan" to the core, and tap all potential to reduce energy consumption and material consumption, reduce carbon emission to the greatest extent, and adhere to low-carbon sewage treatment under the premise of constantly improving the sewage treatment effect.

Global warming is becoming more and more intense, the main reason is the large amount of greenhouse gas carbon dioxide emissions. Therefore, low-carbon production and life are imperative, so in recent years, many scholars put forward the concept of carbon neutrality. In the process of sewage treatment, the COD in sewage is consumed by microorganisms, but the greenhouse gas carbon dioxide is produced and discharged into the air. At the same time, the power consumption in the process of aeration also produces a lot of greenhouse gases. Water pollution is solved but it is transferred into the air. It is roughly estimated that in 2030, the greenhouse gas emissions of China's entire sewage treatment industry will reach 2.95% of the national greenhouse gas emissions. Therefore, it is imperative for the sewage treatment industry to change its direction to achieve low-carbon or even zero-carbon sewage treatment.

One,Carbon neutralization in sewage treatment process

Sewage is actually a carrier of resources and energy. It contains a lot of organic matter, which is a kind of energetic substance, and also contains a lot of phytonutrients (nitrogen, phosphorus and potassium). The essence of sewage treatment is a complex process of separating, degrading and transforming pollutants in sewage (mostly organic pollutants) through artificial complicated technical means, at the expense of resources and energy. In other words, sewage treatment is an energy-consuming carbon emission process, or a gradual evolution from water pollution to air pollution. The traditional sewage treatment means is to use bacteria to metabolize organic matter in sewage. In order to improve the work efficiency, a lot of power is needed to aerate and increase the DO (dissolved oxygen) in water. In this process, bacteria metabolism will produce a lot of CO2, and a lot of CO2 will be produced to provide the power used for aeration.

What are the offsets?

The first is energy consumption, mainly electricity consumption. From the perspective of energy conversion, the essence of traditional sewage treatment mode is energy consumption for water quality. We use a lot of electricity to remove pollutants from sewage, which indirectly produces a lot of carbon dioxide emissions. Second, sewage treatment needs to consume a lot of fuel and pharmaceutical, indirect emissions of a large number of greenhouse gases. In addition, the aerobic stage needs aeration, and a large amount of aeration requires high-power blowers to provide high air volume, and its process power consumption is high.

Through continuous technological innovation, Shuote environmental protection mainly realizes carbon neutrality through energy conservation, emission reduction, resource reuse and other ways.

Two, Shuote environmental protection treatment technology

As shown in the above formula, organic matter COD was oxidized to CO2 directly in this "energy dissipation" way to remove, not as much as possible into renewable energy substances such as CH4 and achieve carbon neutral, so that it can greatly reduce the consumption of external energy (fossil fuels), reducing power and indirect carbon emissions.

1.Anaerobic treatment technology

The sewage first enters the mixing zone at the bottom of the anaerobic reactor, and fully mixes with the internal circulating mud-water mixture from the reflux pipe, and then enters the first reaction chamber for biochemical degradation of pollutants. The COD volume load here is very high, and most influent COD is degraded here, and a large amount of biogas is produced. Biogas is collected by a lower three-phase separator and rises up the reflux line. As the biogas rises, the mixture in the first reaction chamber is lifted to the gas-liquid separator at the top of the IC anaerobic reactor, where the biogas is separated from the sludge and discharged to the reactor. The slurry mixture is returned to the bottom of the reactor along the reflux pipe, and is fully mixed with the influent into the first reaction chamber, forming an internal circulation. The sewage treated by the first reaction chamber will automatically enter the second reaction chamber for further treatment. The biogas generated is collected by the gas collecting hood in the second reaction chamber and enters the gas-water separator through the riser. The mixed liquid in the second reaction chamber is separated by solid and liquid in the precipitation area, the treated supernatant is discharged by the outlet pipe, and the precipitated sludge can be automatically returned to the second reaction chamber.

The main component of anaerobic biogas is methane. Methane is the cleanest energy substance. Biogas can be used as energy after purification, so that the organic pollutants in the water are eventually converted into electricity, which not only reduces the consumption of external energy (fossil fuels). And it avoids converting organic matter into carbon dioxide and releasing it into the atmosphere.

2.Short-cut nitrification and denitrification process technology

1)Fundamentals Traditional biological denitrification process requires two complete nitrification and denitrification process, and the shortcut nitrification and denitrification is to control the nitration process of ammonia nitrogen and nitrate nitrogen, abundant accumulation of nitrate in the system, and then under certain conditions, the system of denitrifying bacteria in organic substrate as electron donor, will the nitrate reduction of nitrogen, Thus achieve the goal of nitrogen removal. The reaction equations are shown in Equations (1-1) and (1-2) :

Nitrosation:NH4+−N + 1.5O2 → NO2‾−N + H+ + H2O (1-1)

Denitrification:6NO2‾−N + 3CH3OH + 3CO2 → 3N2 + 6HCO3‾ + 3H2O (1-2)

Traditional biological denitrification process requires two complete nitrification and denitrification process, and the shortcut nitrification and denitrification is to control the nitration process of ammonia nitrogen and nitrate nitrogen, abundant accumulation of nitrate in the system, and then under certain conditions, the system of denitrifying bacteria in organic substrate as electron donor, will the nitrate reduction of nitrogen, Thus achieve the goal of nitrogen removal. The reaction equations are shown in Equations (1-1) and (1-2) :

Nitrosation:NH4+−N + 1.5O2 → NO2‾−N + H+ + H2O (1-1)

Denitrification:6NO2‾−N + 3CH3OH + 3CO2 → 3N2 + 6HCO3‾ + 3H2O (1-2)

According to the above formula, short-cut nitrification and denitrification is based on NH4+−N→NO2‾−N→N2

2)Technical featuresThe contribution of this technology to carbon neutrality is mainly as follows:

1. Reduce energy consumption. Data show that the power consumption per ton of water in China's sewage treatment plants is generally in the range of 0.15 ~ 0.28kWh. Among them, the power consumption of aerated blower accounts for 56.2%. Although the energy consumption of different treatment processes is different, it is a fact that the total energy consumption of the aeration system is the largest. Therefore, the key point of energy saving and consumption reduction in sewage treatment process is to upgrade the aeration system. Aeration system is mainly to provide dissolved oxygen needed by microorganisms, so the core of energy saving is to accurately control the growth process of microorganisms, to prevent excessive aeration, but also to prevent insufficient aeration. The water consumption per ton is greatly reduced compared with the traditional process. In the process of short-cut nitrification, the oxidation of NH4+-N is controlled at the stage of NO2‾-N, in which the dissolved oxygen is low. The dissolved oxygen of ordinary AO process is ≥2mg/L. Our company will control the dissolved oxygen within 1mg/L, reduce the energy consumption of the fan by about 50%, and obviously save the operation cost.

2. Reuse of energy. In the denitrification process, NO2‾ -n is directly reduced to nitrogen, the required organic carbon source is lower than NO3‾-N reduction nitrogen, the C/N consumed by this technology is about 2.5, and the conventional nitrification and denitrification C/N needs to be greater than 4, at least can save more than 30% of the carbon source, saving this part of the carbon source can be used for the front-end anaerobic system to produce biogas, used for power generation, To realize "turning waste into treasure" and avoid consuming a lot of carbon source in biochemical process.

3. Carbon reduction. After sewage treatment by biochemical process, part of the organic matter in the water under the action of microorganisms, generated their own cell material and sludge, sludge landfill, so as to avoid this part of the organic matter into carbon dioxide emissions into the atmosphere, to achieve the purpose of carbon neutrality.

Three. Actual cases of leachate treatment in Central China

1. Process flow chart

2. Process description

1) Anaerobic nitrification: the leachate can produce biological gas (biogas) through anaerobic nitrification. The main component of biogas produced by anaerobic nitrification is methane. The renewable energy produced by anaerobic nitrification is CH4, which can be incinerated for power generation, so as to achieve carbon neutrality.

2) Biological treatment: two-stage AO process, stage A is full adsorption and transformation of organic matter in the raw sewage, nitrogen and phosphorus will also be significantly reduced due to bacterial synthesis or chemical precipitation; In the O section, organic matter in sewage is removed by biological degradation in the aeration tank. Ordinary NH4+ is oxidized to NO3- through nitrification, and NO3- is removed by denitrification to generate N2. The dissolved oxygen in this process is ≥2mg/L.

3) Sludge concentration: in the AO section of the surplus sludge, first of all to concentrate the sludge, reduce the volume of the surplus sludge.

4) to save carbon source, making full use of leachate in the BOD carbon source for denitrification, and improve the efficiency of energy recovery, reducing the consumption of chemicals with maximum extent, in a broader sense to reduce the whole social resource and energy consumption, and reduce the introduction of chemicals in sewage treatment plant effluent, the mud of the environmental risk.

Four. Future factory

The future is not to transform the sewage treatment station/plant into a single nutrient, energy or reclaimed water plant, but to explore the potential of sewage resources/energy as much as possible, and realize the nutrient, energy and reclaimed water production plant in the same sewage treatment station/plant (NEWs).

So far, there have been some successful practices at home and abroad, and we have reason to believe that China's wastewater treatment industry will soon make a positive contribution to the carbon neutrality strategy. Shuote Environmental Protection will carry out the carbon emission reduction work systematically and comprehensively, follow the national "14th Five-Year Plan" to the core, and tap all potential to reduce energy consumption and material consumption, reduce carbon emission to the greatest extent, and adhere to low-carbon sewage treatment under the premise of constantly improving the sewage treatment effect.

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115