The way out of the full treatment of landfill leachate concentrated Liquid under the new Version of "Pollution Control

From: This site Time: 2022.07.25 View:

On February 28, 2022, the Ministry of Ecology and Environment of The People's Republic of China issued the Pollution Control Standard for Domestic Waste Landfill (Draft for Comments), which caused a great shock in the water treatment industry, especially in the industry of treating landfill leachate by membrane method. In this article, membrane treatment industry practitioners share the impact of the following new standards on membrane treatment companies.

A new version of the standard in the key adjustment

1. The number of pollutant detection items has increased

In the new standard "9.1", the pollutant items in Table 2 and Table 3 are increased from 14 to 20, and the emission limits of the original 14 items remain basically unchanged, but the sampling port in the monitoring position of pollutant discharge of the last 8 items is adjusted to the wastewater discharge port of the leachate regulating pool. More stringent requirements have been put forward on the types of garbage admitted and landfill operations, and the management capacity of landfill sites needs to keep up.

2. Indirect discharge is encouraged and water quality and quantity standards for indirect discharge are clarified

The new standard "9.2" added indirect discharge standards into sewage treatment plants and industrial sewage treatment plants.

Moreover, it is clear in 9.2.3 that "landfill discharges leachate to industrial wastewater treatment plants. Indirect discharge limits for water pollutants in Items 1-11 in Table 4 can be determined through negotiation, and shall be taken as the basis for determination of excess. Unnegotiated water pollutants and items 12-19 shall comply with the water pollutant discharge limits set out in Table 4 ". In other words, as long as the industrial sewage treatment plant treatment capacity is enough, how much leachate can be negotiated.

3. The concentrated liquid generated from the treatment of leachate shall not be reinjected

The new standard "9.3" requires that "9.3.1 only one sewage outlet is allowed in a landfill site; 9.3.2 The concentrated liquid generated from the treatment of leachate shall be disposed of separately and shall not be refed into domestic garbage landfill or into sewage centralized treatment facilities."

It is clear that the concentrated liquid produced by the membrane process cannot be reinjected or entered into the sewage centralized treatment facility, and must be treated separately. In the case of a full landfill site with only one effluent outlet, the water quality of the concentrated solution after treatment should also meet the requirements of Table 2, Table 3 or Table 4 (indirect discharge). The space of double film method and DTRO is greatly reduced. Simple double-membrane and DTRO processes can still be done and are cost-effective considering the cost of processing the concentrate.

Opportunities for membrane treatment of leachate concentrate under new standards

The existing landfill with leachate treatment by recharge treatment will stop recharge treatment, will undergo a large number of technological transformation. Referring to the idea of 2008 standard, generally will set 2-3 years of buffer time. Bring short - term explosion to non - recharge treatment market.

At the same time, there is no TDS requirement in the new standard, and the Water Quality Standard for Sewage Discharged into Urban sewage (GBT31962-2015) clearly stipulates that the limit value of the total dissolved solids in the pipe entering the sewage plant is 1500-2000mg/L, while most industrial sewage plants will also require the total salt is not higher than 5000mg/L. The actual implementation is quite a test of the coordination ability of the local government, otherwise there will be contradictions in the implementation, and the indirect discharge of leachate will be greatly delayed. The direct discharge process of non - recharge full treatment will be more competitive.

3. Current situation and difficulties of leachate concentrated liquid treatment industry

Landfill leachate membrane concentrate is a byproduct of landfill leachate treatment by membrane technology. Compared with landfill leachate, its concentration of organic pollutants, inorganic salts and metal ions is higher, and its biochemical properties are poor. Improper disposal will cause more serious secondary pollution. At present, the main technology of concentrated liquid is recharge, advanced oxidation, evaporation and the combined technology as the core.

1. Concentrated liquid recharge

The recharging process uses the landfill as a bioreactor, which is simple in construction and low in cost.

Although the recirculation process can remove certain pollutants, with the passing of time, salt and refractory organic matter will accumulate in the leachate, which makes the membrane treatment process of the front-end leachate difficult to operate. At the same time, article 9.3.2 of the new version of The Pollution Control Standard for Domestic waste Landfill clearly requires: "The concentrated liquid generated from the treatment of leachate should be separately disposed, and shall not be refed into domestic waste landfill or into sewage centralized treatment facilities". When the new standard was implemented, recharging of concentrate was prohibited.

2. Advanced oxidation

Advanced oxidation is the concentration of advanced oxidation treatment (mainly fenton, ozone, electrolysis, etc.), generally in combination with other processes. Stable operation and good reliability.

Advanced oxidation technology is mature in the field of municipal wastewater and industrial wastewater treatment, but there are some problems in the treatment of concentrated solution. Fenton method large dosage of reagents, long reaction time, low pH requirements, large amount of sludge, easy to cause secondary pollution; Ozone method has high energy consumption and high selectivity. Electrolysis anode material cost is high and current efficiency is limited. It is difficult for each method to meet the discharge standard when treating concentrated liquid separately, so it must be combined with other processes.

3. Evaporation process

Evaporation is the physical process by which volatile and non-volatile components are separated. When a concentrate is treated by evaporation, water boils out of the solution and contaminants end up in the concentrate. At present, the commonly used evaporation technology at home and abroad are immersion combustion evaporation (SCE) technology and mechanical steam recompression (MVC/MVR) technology.

SCE technology can make full use of LFG (landfill gas) in landfills, eliminate environmental pollution and improve energy efficiency. However, the removal effect of NH3-N is not ideal. At the same time, the concentration of chloride ions in the concentrate may corrode the equipment during system heating.

MVC/MVR technology is an energy-saving technology that utilizes the secondary steam and its energy generated by the evaporation system itself to improve the heat energy of the secondary steam through the compression work done by the steam compressor, so as to circulate heat to the evaporation system and reduce the demand for external energy. At present, MVC/MVR technology is mainly applied to the treatment of leachate, and there are problems such as scaling and cleaning in the process of treatment.

The safe disposal of secondary concentrate is the key problem to be solved in evaporation process. According to the physical and chemical characteristics of the secondary concentrate, incineration can be adopted for disposal, or dehydration and desiccation can be followed by embedding and solidified to landfill. However, incineration will not only affect the calorific value of garbage, but also easily corrode incineration facilities; Direct filling in the landfill will lead to the accumulation of inorganic salts and refractory pollutants in the concentrated solution and increase of electrical conductivity, which will cause serious scaling in the subsequent reverse osmosis process and decrease of effluent rate. In serious cases, the concentrated solution treatment system will be paralyzed.

4. Shuote technology's low consumption and high efficiency fully quantified leachate concentration treatment process

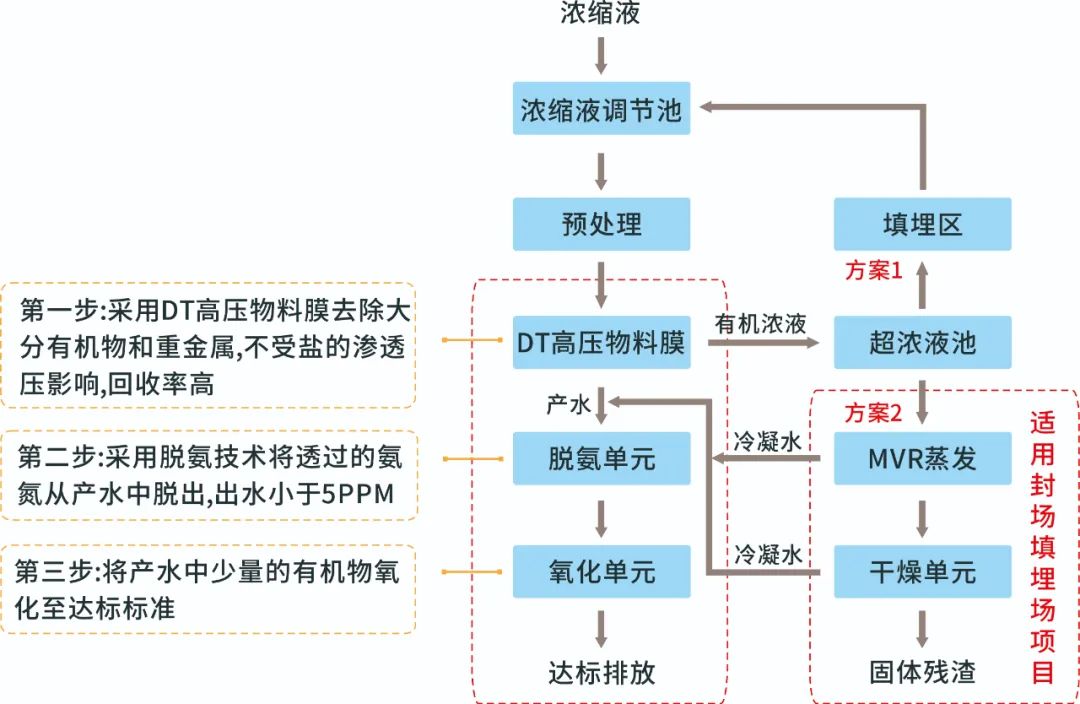

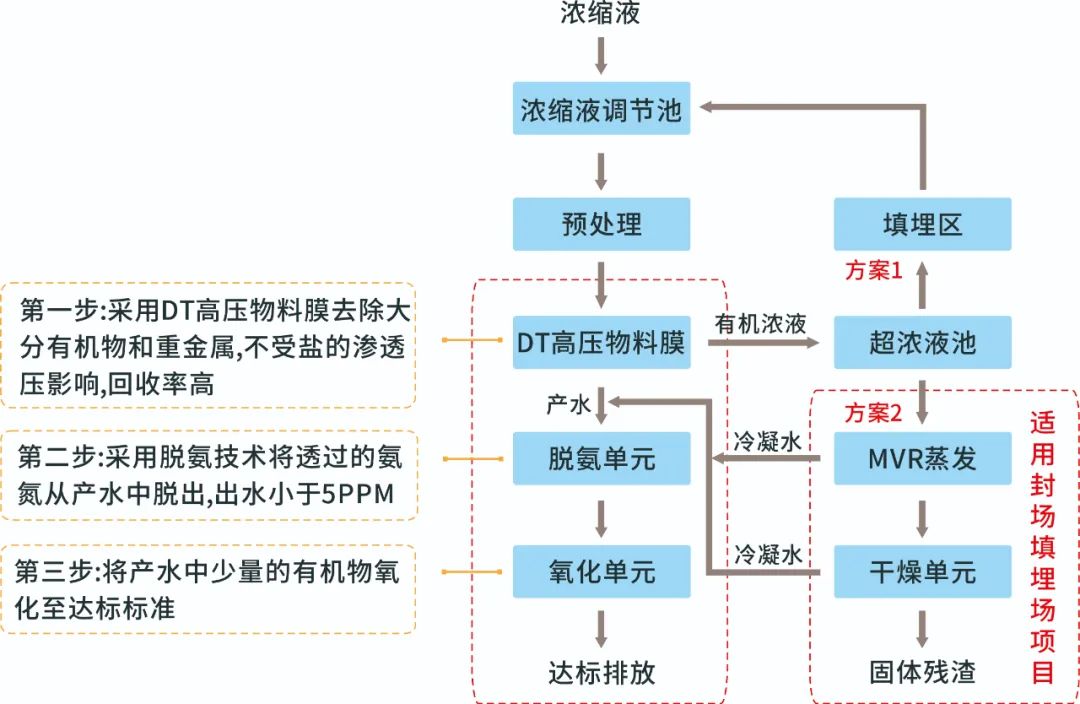

TLD non-evaporative full process

Scope of application: This process is mainly used for old landfill leachate or DTRO membrane concentrate.

Process instructions:

1. Pretreatment mainly removes suspended solids with particle size above 10μm from the concentrated leachate to protect the subsequent operation of the membrane system.

2.DT high pressure material film adopts special material film, concentrated water contains most organic matter, heavy metal and bivalent salt, recovery rate can reach more than 80%, COD concentration of produced water is less than 100ppm.

3. The ammonia removal unit adopts special material diaphragm for ammonia nitrogen, which can control the effluent ammonia nitrogen below 5ppm.

4. Oxidation unit adopts catalytic oxidation technology to remove residual COD and ensure effluent quality.

Other:

1. The ammonium sulfate recovered or reinjected into the landfill and part of the treated nutrient solution are beneficial to the ecological restoration of the landfill, which can provide nutrients for microorganisms and plants and achieve the full treatment of leachate.

2. If the ultra-thick liquid can not be reflow, the process of "evaporation + drying" can be used for treatment.

Process features:

1. The effluent is stable enough to meet or even better than the table 2 standard of Domestic Waste Landfill Pollution Control Standard GB16889-2008.

2. After the separated concentrated water is returned to the landfill, the organic pollutants in the water are removed by microbial degradation to achieve the full treatment of leachate.

3. The univalent salt is discharged with the standard water system, and the bivalent salt Ca2+ and SO42- are deposited with the concentrated water back to the landfill after precipitation, completely solving the problem of salt accumulation, and ensuring that the effluent rate continues to reach the design value.

4. The system is highly integrated, modular, small footprint and short construction cycle.

5. Advantages of low consumption and high efficiency full quantization leachate concentration treatment process

In response to national strategic policies such as carbon peak and carbon neutralization, And by absorbing the advantages of mainstream technology and combining with its unique membrane separation technology, Suotec has successfully developed a full non-evaporative TLD process with hundreds of strengths. Realized "membrane treatment", "advanced oxidation", "evaporation" and other processes organic combination. Compared with the existing "recharge", "advanced oxidation" and "evaporation" processes, it has the following advantages:

1. Complete treatment of leachate can be realized

The ultra-concentrated liquid separated by TLD process (membrane treatment part) is treated with "evaporation + drying", which can realize the full treatment of leachate without secondary pollution.

2. Stable and efficient operation

TLD process (membrane treatment part) enables the separation of concentrated solution, which facilitates the classification of treatment. The water production part is mainly a small amount of organic matter and monovalent salt. After recovering ammonia nitrogen, the "advanced oxidation" process is adopted, which greatly reduces the pressure of advanced oxidation. The ultra-concentrated liquid is mainly organic matter and bivalent salt, and mainly adopts the "evaporation" process. Compared with the direct evaporation of concentrated liquid, the treated water is greatly reduced.

After purifying and diverting the concentrated solution, the water quality of TLD process (membrane treatment part) is stable and the molecular weight of organic matter is small, which is conducive to the operation of TLD process (advanced oxidation part - ozone-catalyzed oxidation). It avoids the oxidation selectivity and the situation that the water can't reach the standard. Compared with the combination of "advanced oxidation + biochemical", it adopts a large number of total physical and chemical methods, and runs more stably and efficiently. Water production is more reliable.

3. Low energy consumption and drug consumption

TLD process (membrane treatment part) can realize the separation of concentrated solution, which can realize the classification of sewage treatment, higher efficiency. TLD process (advanced oxidation part) adopts "ozone-catalyzed oxidation" process, no large amount of additional agents, no secondary sludge. The TLD process (evaporation part) is introduced, and landfill gas can be used. At the same time, due to the role of membrane treatment part, evaporation is less. In most cases, only landfill gas can meet the evaporation requirements.

The comprehensive water and power consumption per ton of TLD process is 35-40kwh, which greatly reduces the energy consumption compared with the comprehensive water and power consumption per ton of "evaporation + membrane treatment" of 80-90kwh.

6. Typical cases of Shuort Technology

Case 1: Zigong concentrated liquid full quantitative treatment project

Zigong City Urban and rural Waste Treatment Center is located in Yantan District, Zigong City. Founded in 1995, it covers an area of 150 mu with a total storage capacity of 1.8462 million m³. It is designed to treat 400 tons of waste per day and closed in 2013. In 2014, according to the assessment standard for the establishment of a National Garden city, the landfill leachate was entrusted to Zigong Nengduxi Garbage Power Plant for treatment. However, due to the limited treatment capacity of the leachate treatment system supporting the incineration power plant, a large amount of leachate was accumulated in the plant's regulating pond for many years. In order to speed up the full disposal of the existing leachate in the landfill area D and E of zigong Urban and rural waste treatment center, the government procurement method was adopted for full treatment (including concentrated liquid treatment).

Processing scale: 300T /d

Treatment process: pretreatment +DTRO system + high pressure material membrane system + ammonia recovery system + catalytic oxidation system + electrolytic oxidation system + ion exchange system + ultra concentrated liquid treatment

Effluent standard: meet table 3 standard of Pollution Control Standard for Domestic waste Landfill GB16889-2008

Case 2: Renshou landfill leachate concentration full treatment project

Garden.empress landfill site to be built and put into production in 2008, belongs to the old landfill, leachate can be biochemical reduced gradually, and as a result of long-term concentrate recharge, salt increased, leachate conductivity increased up to 56000 mu (s/cm), to concentrate, to reduce the leachate treatment of existing load and operation pressure, In the elimination of environmental risks at the same time truly achieve full treatment.

Processing scale: 300T /d

Treatment process: pretreatment + high pressure material membrane treatment + ammonia recovery + catalytic oxidation

Effluent standard: the effluent quality after treatment meets the table 2 standard of Domestic Waste Landfill Pollution Control Standard (GB16889-2008)

Case 3: Full leachate disposal service project of Jianyang Municipal Solid Waste Treatment Plant

Jianyang Municipal Solid waste Treatment Plant is located in Wushe, Xinqiao Village, Pingquan Town, Jianyang City. It was built by Jianyang Environmental Sanitation Management Institute in 2004, with a total storage capacity of 1.9 million m³, which requires full treatment of landfill leachate. Due to the landfill operation time is long, belong to the old landfill, leachate biodegradability gradually decreased, and because of the long-term concentrated liquid recharge, salt accumulation, electrical conductivity has been as high as 35,000 μS/cm. The daily treatment capacity of this project is required to be no less than 200t/d, and the total recovery rate of the system design is 95%. The effluent water quality after treatment meets the standards listed in Table 2 of Pollution Control Standard for Domestic Garbage Landfill (GB16889-2008), and the discharge shall meet the standards.

Processing scale: 200T /d

Treatment process: pretreatment + two-stage dish reverse osmosis +COD high pressure membrane separation system + ammonia recovery + catalytic oxidation

Effluent standard: the effluent quality after treatment meets the table 2 standard of Pollution Control Standard for Domestic Waste Landfill (GB16889-2008)

Case 4: Chongqing Landfill concentrated liquid evaporation mother liquid treatment project

The concentrated leachate from Chongqing landfill was treated by "pretreatment +RO+ evaporation" process and then the evaporated mother liquor was dried.

Processing scale: 1000T /d

Treatment process: biogas pretreatment + steam boiler +MVR+ low temperature drying

Mud discharge standard: water content ≤20%

A new version of the standard in the key adjustment

1. The number of pollutant detection items has increased

In the new standard "9.1", the pollutant items in Table 2 and Table 3 are increased from 14 to 20, and the emission limits of the original 14 items remain basically unchanged, but the sampling port in the monitoring position of pollutant discharge of the last 8 items is adjusted to the wastewater discharge port of the leachate regulating pool. More stringent requirements have been put forward on the types of garbage admitted and landfill operations, and the management capacity of landfill sites needs to keep up.

2. Indirect discharge is encouraged and water quality and quantity standards for indirect discharge are clarified

The new standard "9.2" added indirect discharge standards into sewage treatment plants and industrial sewage treatment plants.

Moreover, it is clear in 9.2.3 that "landfill discharges leachate to industrial wastewater treatment plants. Indirect discharge limits for water pollutants in Items 1-11 in Table 4 can be determined through negotiation, and shall be taken as the basis for determination of excess. Unnegotiated water pollutants and items 12-19 shall comply with the water pollutant discharge limits set out in Table 4 ". In other words, as long as the industrial sewage treatment plant treatment capacity is enough, how much leachate can be negotiated.

3. The concentrated liquid generated from the treatment of leachate shall not be reinjected

The new standard "9.3" requires that "9.3.1 only one sewage outlet is allowed in a landfill site; 9.3.2 The concentrated liquid generated from the treatment of leachate shall be disposed of separately and shall not be refed into domestic garbage landfill or into sewage centralized treatment facilities."

It is clear that the concentrated liquid produced by the membrane process cannot be reinjected or entered into the sewage centralized treatment facility, and must be treated separately. In the case of a full landfill site with only one effluent outlet, the water quality of the concentrated solution after treatment should also meet the requirements of Table 2, Table 3 or Table 4 (indirect discharge). The space of double film method and DTRO is greatly reduced. Simple double-membrane and DTRO processes can still be done and are cost-effective considering the cost of processing the concentrate.

Opportunities for membrane treatment of leachate concentrate under new standards

The existing landfill with leachate treatment by recharge treatment will stop recharge treatment, will undergo a large number of technological transformation. Referring to the idea of 2008 standard, generally will set 2-3 years of buffer time. Bring short - term explosion to non - recharge treatment market.

At the same time, there is no TDS requirement in the new standard, and the Water Quality Standard for Sewage Discharged into Urban sewage (GBT31962-2015) clearly stipulates that the limit value of the total dissolved solids in the pipe entering the sewage plant is 1500-2000mg/L, while most industrial sewage plants will also require the total salt is not higher than 5000mg/L. The actual implementation is quite a test of the coordination ability of the local government, otherwise there will be contradictions in the implementation, and the indirect discharge of leachate will be greatly delayed. The direct discharge process of non - recharge full treatment will be more competitive.

3. Current situation and difficulties of leachate concentrated liquid treatment industry

Landfill leachate membrane concentrate is a byproduct of landfill leachate treatment by membrane technology. Compared with landfill leachate, its concentration of organic pollutants, inorganic salts and metal ions is higher, and its biochemical properties are poor. Improper disposal will cause more serious secondary pollution. At present, the main technology of concentrated liquid is recharge, advanced oxidation, evaporation and the combined technology as the core.

1. Concentrated liquid recharge

The recharging process uses the landfill as a bioreactor, which is simple in construction and low in cost.

Although the recirculation process can remove certain pollutants, with the passing of time, salt and refractory organic matter will accumulate in the leachate, which makes the membrane treatment process of the front-end leachate difficult to operate. At the same time, article 9.3.2 of the new version of The Pollution Control Standard for Domestic waste Landfill clearly requires: "The concentrated liquid generated from the treatment of leachate should be separately disposed, and shall not be refed into domestic waste landfill or into sewage centralized treatment facilities". When the new standard was implemented, recharging of concentrate was prohibited.

2. Advanced oxidation

Advanced oxidation is the concentration of advanced oxidation treatment (mainly fenton, ozone, electrolysis, etc.), generally in combination with other processes. Stable operation and good reliability.

Advanced oxidation technology is mature in the field of municipal wastewater and industrial wastewater treatment, but there are some problems in the treatment of concentrated solution. Fenton method large dosage of reagents, long reaction time, low pH requirements, large amount of sludge, easy to cause secondary pollution; Ozone method has high energy consumption and high selectivity. Electrolysis anode material cost is high and current efficiency is limited. It is difficult for each method to meet the discharge standard when treating concentrated liquid separately, so it must be combined with other processes.

3. Evaporation process

Evaporation is the physical process by which volatile and non-volatile components are separated. When a concentrate is treated by evaporation, water boils out of the solution and contaminants end up in the concentrate. At present, the commonly used evaporation technology at home and abroad are immersion combustion evaporation (SCE) technology and mechanical steam recompression (MVC/MVR) technology.

SCE technology can make full use of LFG (landfill gas) in landfills, eliminate environmental pollution and improve energy efficiency. However, the removal effect of NH3-N is not ideal. At the same time, the concentration of chloride ions in the concentrate may corrode the equipment during system heating.

MVC/MVR technology is an energy-saving technology that utilizes the secondary steam and its energy generated by the evaporation system itself to improve the heat energy of the secondary steam through the compression work done by the steam compressor, so as to circulate heat to the evaporation system and reduce the demand for external energy. At present, MVC/MVR technology is mainly applied to the treatment of leachate, and there are problems such as scaling and cleaning in the process of treatment.

The safe disposal of secondary concentrate is the key problem to be solved in evaporation process. According to the physical and chemical characteristics of the secondary concentrate, incineration can be adopted for disposal, or dehydration and desiccation can be followed by embedding and solidified to landfill. However, incineration will not only affect the calorific value of garbage, but also easily corrode incineration facilities; Direct filling in the landfill will lead to the accumulation of inorganic salts and refractory pollutants in the concentrated solution and increase of electrical conductivity, which will cause serious scaling in the subsequent reverse osmosis process and decrease of effluent rate. In serious cases, the concentrated solution treatment system will be paralyzed.

4. Shuote technology's low consumption and high efficiency fully quantified leachate concentration treatment process

TLD non-evaporative full process

Scope of application: This process is mainly used for old landfill leachate or DTRO membrane concentrate.

Process instructions:

1. Pretreatment mainly removes suspended solids with particle size above 10μm from the concentrated leachate to protect the subsequent operation of the membrane system.

2.DT high pressure material film adopts special material film, concentrated water contains most organic matter, heavy metal and bivalent salt, recovery rate can reach more than 80%, COD concentration of produced water is less than 100ppm.

3. The ammonia removal unit adopts special material diaphragm for ammonia nitrogen, which can control the effluent ammonia nitrogen below 5ppm.

4. Oxidation unit adopts catalytic oxidation technology to remove residual COD and ensure effluent quality.

Other:

1. The ammonium sulfate recovered or reinjected into the landfill and part of the treated nutrient solution are beneficial to the ecological restoration of the landfill, which can provide nutrients for microorganisms and plants and achieve the full treatment of leachate.

2. If the ultra-thick liquid can not be reflow, the process of "evaporation + drying" can be used for treatment.

Process features:

1. The effluent is stable enough to meet or even better than the table 2 standard of Domestic Waste Landfill Pollution Control Standard GB16889-2008.

2. After the separated concentrated water is returned to the landfill, the organic pollutants in the water are removed by microbial degradation to achieve the full treatment of leachate.

3. The univalent salt is discharged with the standard water system, and the bivalent salt Ca2+ and SO42- are deposited with the concentrated water back to the landfill after precipitation, completely solving the problem of salt accumulation, and ensuring that the effluent rate continues to reach the design value.

4. The system is highly integrated, modular, small footprint and short construction cycle.

5. Advantages of low consumption and high efficiency full quantization leachate concentration treatment process

In response to national strategic policies such as carbon peak and carbon neutralization, And by absorbing the advantages of mainstream technology and combining with its unique membrane separation technology, Suotec has successfully developed a full non-evaporative TLD process with hundreds of strengths. Realized "membrane treatment", "advanced oxidation", "evaporation" and other processes organic combination. Compared with the existing "recharge", "advanced oxidation" and "evaporation" processes, it has the following advantages:

1. Complete treatment of leachate can be realized

The ultra-concentrated liquid separated by TLD process (membrane treatment part) is treated with "evaporation + drying", which can realize the full treatment of leachate without secondary pollution.

2. Stable and efficient operation

TLD process (membrane treatment part) enables the separation of concentrated solution, which facilitates the classification of treatment. The water production part is mainly a small amount of organic matter and monovalent salt. After recovering ammonia nitrogen, the "advanced oxidation" process is adopted, which greatly reduces the pressure of advanced oxidation. The ultra-concentrated liquid is mainly organic matter and bivalent salt, and mainly adopts the "evaporation" process. Compared with the direct evaporation of concentrated liquid, the treated water is greatly reduced.

After purifying and diverting the concentrated solution, the water quality of TLD process (membrane treatment part) is stable and the molecular weight of organic matter is small, which is conducive to the operation of TLD process (advanced oxidation part - ozone-catalyzed oxidation). It avoids the oxidation selectivity and the situation that the water can't reach the standard. Compared with the combination of "advanced oxidation + biochemical", it adopts a large number of total physical and chemical methods, and runs more stably and efficiently. Water production is more reliable.

3. Low energy consumption and drug consumption

TLD process (membrane treatment part) can realize the separation of concentrated solution, which can realize the classification of sewage treatment, higher efficiency. TLD process (advanced oxidation part) adopts "ozone-catalyzed oxidation" process, no large amount of additional agents, no secondary sludge. The TLD process (evaporation part) is introduced, and landfill gas can be used. At the same time, due to the role of membrane treatment part, evaporation is less. In most cases, only landfill gas can meet the evaporation requirements.

The comprehensive water and power consumption per ton of TLD process is 35-40kwh, which greatly reduces the energy consumption compared with the comprehensive water and power consumption per ton of "evaporation + membrane treatment" of 80-90kwh.

6. Typical cases of Shuort Technology

Case 1: Zigong concentrated liquid full quantitative treatment project

Zigong City Urban and rural Waste Treatment Center is located in Yantan District, Zigong City. Founded in 1995, it covers an area of 150 mu with a total storage capacity of 1.8462 million m³. It is designed to treat 400 tons of waste per day and closed in 2013. In 2014, according to the assessment standard for the establishment of a National Garden city, the landfill leachate was entrusted to Zigong Nengduxi Garbage Power Plant for treatment. However, due to the limited treatment capacity of the leachate treatment system supporting the incineration power plant, a large amount of leachate was accumulated in the plant's regulating pond for many years. In order to speed up the full disposal of the existing leachate in the landfill area D and E of zigong Urban and rural waste treatment center, the government procurement method was adopted for full treatment (including concentrated liquid treatment).

Processing scale: 300T /d

Treatment process: pretreatment +DTRO system + high pressure material membrane system + ammonia recovery system + catalytic oxidation system + electrolytic oxidation system + ion exchange system + ultra concentrated liquid treatment

Effluent standard: meet table 3 standard of Pollution Control Standard for Domestic waste Landfill GB16889-2008

Case 2: Renshou landfill leachate concentration full treatment project

Garden.empress landfill site to be built and put into production in 2008, belongs to the old landfill, leachate can be biochemical reduced gradually, and as a result of long-term concentrate recharge, salt increased, leachate conductivity increased up to 56000 mu (s/cm), to concentrate, to reduce the leachate treatment of existing load and operation pressure, In the elimination of environmental risks at the same time truly achieve full treatment.

Processing scale: 300T /d

Treatment process: pretreatment + high pressure material membrane treatment + ammonia recovery + catalytic oxidation

Effluent standard: the effluent quality after treatment meets the table 2 standard of Domestic Waste Landfill Pollution Control Standard (GB16889-2008)

Case 3: Full leachate disposal service project of Jianyang Municipal Solid Waste Treatment Plant

Jianyang Municipal Solid waste Treatment Plant is located in Wushe, Xinqiao Village, Pingquan Town, Jianyang City. It was built by Jianyang Environmental Sanitation Management Institute in 2004, with a total storage capacity of 1.9 million m³, which requires full treatment of landfill leachate. Due to the landfill operation time is long, belong to the old landfill, leachate biodegradability gradually decreased, and because of the long-term concentrated liquid recharge, salt accumulation, electrical conductivity has been as high as 35,000 μS/cm. The daily treatment capacity of this project is required to be no less than 200t/d, and the total recovery rate of the system design is 95%. The effluent water quality after treatment meets the standards listed in Table 2 of Pollution Control Standard for Domestic Garbage Landfill (GB16889-2008), and the discharge shall meet the standards.

Processing scale: 200T /d

Treatment process: pretreatment + two-stage dish reverse osmosis +COD high pressure membrane separation system + ammonia recovery + catalytic oxidation

Effluent standard: the effluent quality after treatment meets the table 2 standard of Pollution Control Standard for Domestic Waste Landfill (GB16889-2008)

Case 4: Chongqing Landfill concentrated liquid evaporation mother liquid treatment project

The concentrated leachate from Chongqing landfill was treated by "pretreatment +RO+ evaporation" process and then the evaporated mother liquor was dried.

Processing scale: 1000T /d

Treatment process: biogas pretreatment + steam boiler +MVR+ low temperature drying

Mud discharge standard: water content ≤20%

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115