Summary of oil and gas field sewage treatment and comprehensive utilization in oil and gas industry

From: This site Time: 2022.07.25 View:

Traditionally, oil and gas field sewage treatment mainly adopts the methods of air flotation, coagulation and sedimentation, filtration and so on, which cannot effectively meet the current environmental protection requirements. Therefore, more efficient water treatment technology needs to be developed for treatment. Based on some engineering cases and combined with the current development situation of oil and gas fields in China, this paper will discuss the new technology and comprehensive application of oil and gas field sewage treatment and the extraction of oil and gas field water resources, especially sodium and lithium resources, to turn waste into treasure and realize resource utilization, laying a foundation for the better realization of sustainable development of oil and gas fields.

With the increase of oil and gas exploration, the number of gas Wells is gradually increasing, and the resulting sewage water is also increasing year by year. The sewage from oil and gas fields has complex components and strong pollution. If it is discharged directly without treatment, it will seriously damage the ecological environment and affect the sustainable exploitation and development of oil and gas fields. How to efficiently treat oil and gas field sewage to achieve the goal of external discharge and reuse, scientific development of oil and gas field sewage treatment, oil and gas field economic benefits and social benefits have a very important significance.

First, the nature of oil and gas field sewage and its harm to the environment

The sewage from oil and gas fields comes from the associated water produced in the process of oil and gas production. In order to obtain qualified oil and gas products, it is necessary to separate the associated water from oil and gas. After separation, the associated water contains a certain amount of crude oil and other impurities. These separated associated water is called oil and gas field sewage.

The sewage from oil and gas fields is directly injected into the formation without effective treatment, which not only has a great influence on the next exploitation, but also has a great harm to the production facilities, and may destroy the formation structure at last.

Second, domestic oil and gas field sewage treatment status

At present, the sewage treatment technologies of oil and gas fields are mainly physical, chemical and biological methods.

Physical method mainly through centrifugation or gravity separation, so that oil impurities, solid suspended matter and minerals in sewage are separated from sewage by centrifugal force or gravity. The method is simple and easy to operate, but the removal degree of harmful substances can not be guaranteed.

Chemical method commonly used chemical reagents, neutralization, chemical process and three methods such as coagulation precipitation chemical treatment method is mainly deal with object for the solubility of water substance and colloid, chemical processing method can effectively improving the quality of sewage treatment, but chemical reagent itself is pollutants, such as improper handling may cause secondary pollution.

Biological treatment is generally achieved through the cultivation of microorganisms that can degrade harmful substances in sewage. At present, the biological treatment generally divided into aerobic biological process, anaerobic biological method and three kinds of aerobic and anaerobic biological method, it can improve quality of wastewater treatment, and won't cause pollution to the environment, but the biological treatment system covers an area of big, long residence time, lower to higher levels of sewage treatment capacity, higher requirements on the processing environment.

The above treatment methods have low efficiency and poor quality of produced water. At present, environmental protection requirements are improved, and more efficient technologies are needed to meet standards for discharge, reuse or zero discharge.

3. Processing technology and advantages of Chengdu Shuote Technology Co., LTD

In the oil and gas field sewage treatment industry, Chengdu Shuote Technology Co., LTD. (hereinafter referred to as "Shuote technology") is the first company in China to adopt high pressure reverse osmosis technology for large-scale engineering application. It has engineering cases of different water quality in many domestic blocks and has quite mature engineering application experience.

According to the different characteristics of various sewage from oil and gas fields, Shuote technology adopts the combination of air flotation, high-density pool, catalytic oxidation and other technologies to pretreat the sewage and remove pollutants such as petroleum, acid and alkali, guanidine gum, calcium and magnesium hardness and organic matter in the water. The pre-treated sewage was reduced concentration and desalted by high pressure reverse osmosis, RO, NF membrane separation processes. The concentrated high-salt wastewater can be recycled by MVR, drying (low-temperature evaporation) and so on.

Main process:

Pretreatment process: air flotation process is used to remove petroleum pollutants in sewage.

The high density precipitation technology was used to remove hardness ions such as calcium and magnesium and other heavy metal ions from water.

Guanidine gum and organic matter in water were removed by catalytic oxidation technology.

Membrane separation process: high pressure reverse osmosis process is used to concentrate sewage to achieve the concentration and reduction of sewage;

RO process can guarantee the further treatment of high pressure reverse osmosis effluent, so that the effluent COD, ammonia nitrogen, salt and other contents are lower.

NF is used for salt separation treatment of sewage to ensure the quality of salt produced by evaporation.

Evaporation process: using MVR process to recycle salt;

The residual mother liquor was treated by drying (evaporation at low temperature).

Aiming at the oil and gas field sewage in different regions and with different water quality, Shuote technology adopts different technology combinations to carry out zero discharge treatment of oil and gas field sewage through "pretreatment + membrane treatment + evaporation", so as to realize reasonable recovery and utilization of water and salt resources.

According to the process design

Process features:

1. Use catalytic oxidation process to oxidize guanidine gum and other macromolecular organic matter in water;

2. Adopt high-density precipitation technology to remove hardness ions such as calcium and magnesium in incoming water;

3. Advanced oxidation technology is adopted to further remove COD in incoming water to ensure that the water produced by high-pressure membrane can meet standards and be discharged externally;

4. Using high pressure reverse osmosis concentration technology to achieve salt concentration;

5. Salt separation can be realized by nanofiltration technology;

6. Adopt MVR evaporation technology to achieve zero discharge of wastewater.

Advantage:

1. Good anti-pollution performance: highly resistant to COD, adapt to water quality fluctuations in a large range, and stable water quality;

2. Good treatment effect: the effluent water quality directly meets the discharge standard listed in Table 1 of "Water Quality of Industrial Water for Urban Sewage Recycling" (GB/T19923-2005);

3. High-doubling reduction of sewage: high-doubling concentration of concentrated brine, reducing the amount of evaporation;

4. High equipment integration: modular equipment, easy to move and process combination;

5. Low power of equipment: low operating power of a single set of equipment, suitable for mobile power supply of wellsite;

6. Zero emission: the whole process system can ensure the final salt quality and achieve zero emission.

Extraction of lithium resources in oil and gas fields:

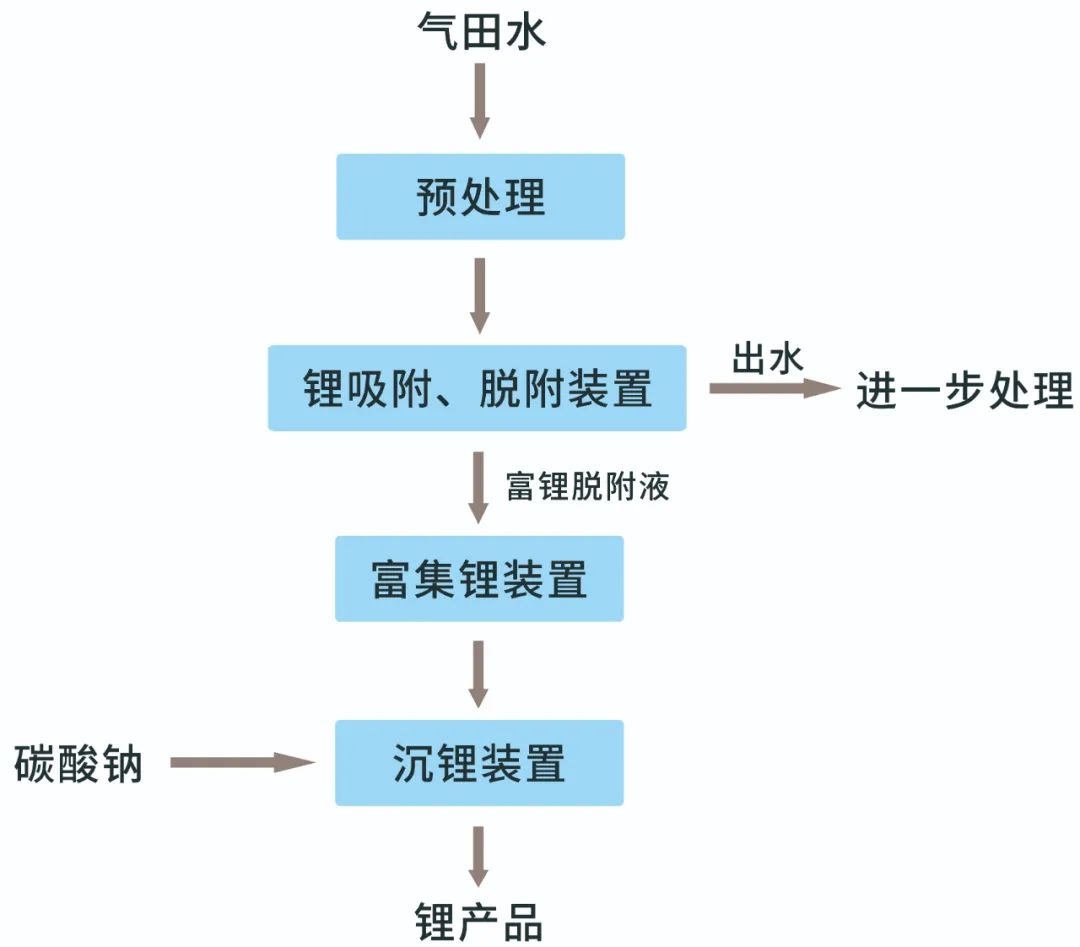

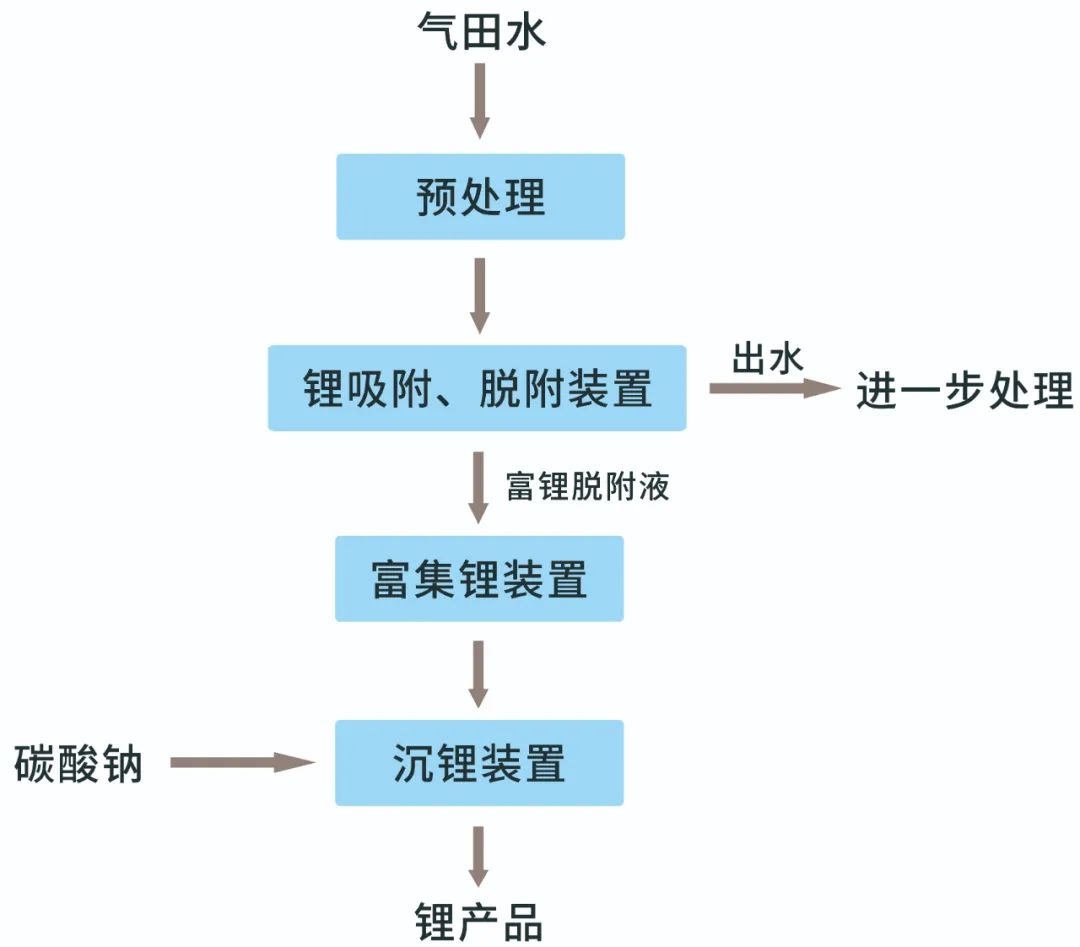

There are lithium, potassium, boron, bromine and other mineral resources in the water of oil and gas fields. It is found that the content of lithium, potassium, boron, bromine and other mineral resources in the water of many oil and gas fields in China is higher than the lowest industrial grade, which has potential resource utilization value. Survey and assessment project from shale gas resources in sichuan province, according to final results acceptance meeting for five years, the project found that, more than 40 trillion cubic meters of shale gas geology resources of sichuan province technical recoverable resources of about 9 trillion cubic meters, economic recoverable resources of about 5 trillion cubic meters, and some parts of the lithium content is extremely high, to carry out the technology of extracting lithium from oil and gas field water application has great economic value.

Iv. Cases of shuotec Oil and gas field sewage treatment self-built station and comprehensive utilization

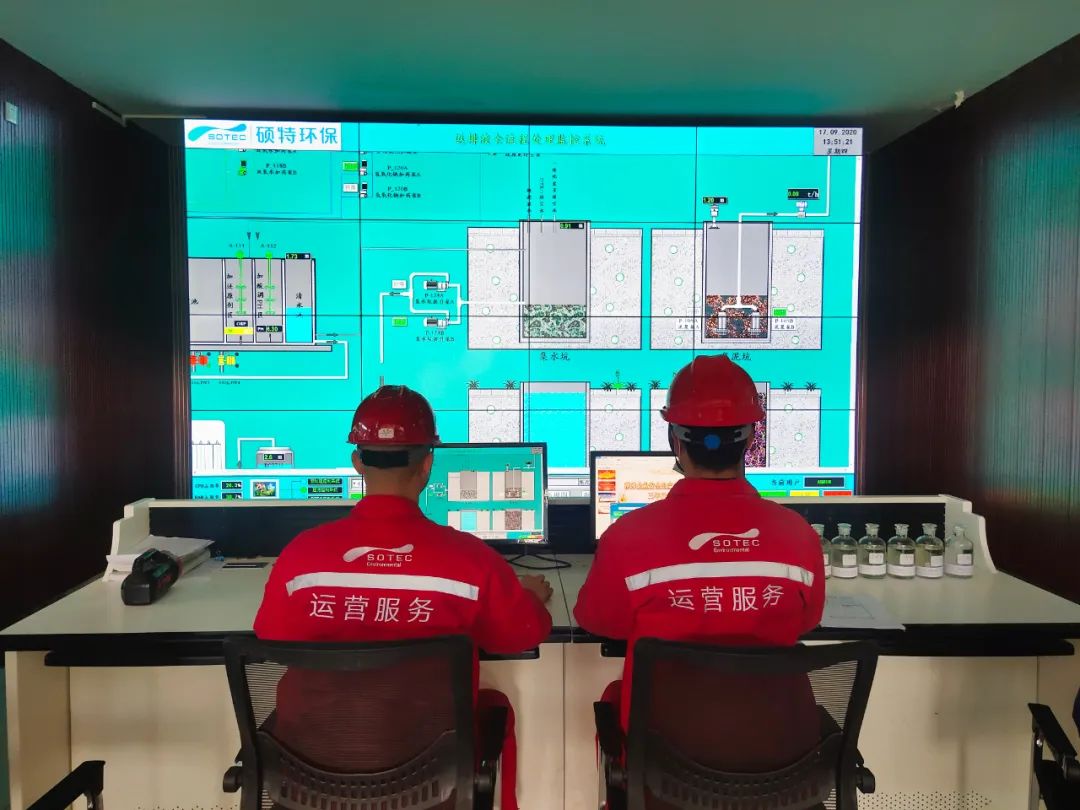

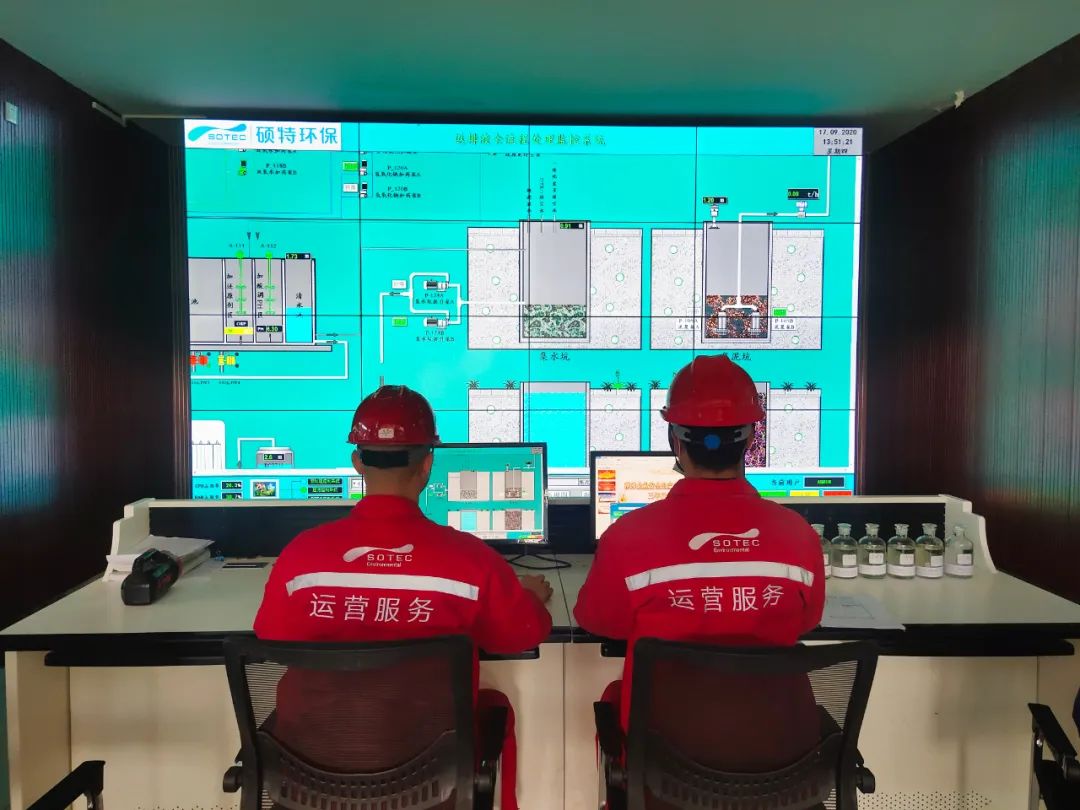

Shuote technology has built two water treatment stations in Zigong Jiuda and Suining Botong to provide supporting services for the whole process of oil and gas field water treatment from "pretreatment + concentration and reduction + resource recovery (first-class industrial product, applied in chlor-alkali chemical industry)", striving to become a leading comprehensive service provider of sewage treatment in the oil and gas field.

Suining Botong Technology Co., LTD. Industrial sewage treatment plant

The treatment plant is located in Longping Street, Suining Economic and Technological Development Zone. The eia approval was obtained in 2021 (then the EIA Letter [2021] No. 28). The first-phase treatment scale is 400m³/d, mainly dealing with sewage from atmospheric mine fields around the project, including drilling wastewater, gas field water, completion sewage (fracturing and gas test flowback fluid), etc. The quality of the produced water reaches grade A of Discharge Standard of Pollutants from Urban Sewage Treatment Plant (GB18918 -- 2002), and the chloride reaches grade A of Discharge Standard of Pollutants from Water of Sichuan Province (DB51/190-93).

Zigong Jiuda 500,000 m3 / year shale gas field water treatment plant

The treatment plant is located in the factory of Dengguan Branch of Jiuda Group, Dengguan Town, Yantan District, Zigong City, Sichuan Province. The plant treats the produced water from the gas field produced in the production process of shale gas mining area and uses it back to the standard. The total daily water treatment scale of shale gas field in the treatment plant is 1500m³/d. This project adopts pretreatment + membrane concentration and evaporation concentration processing technology.

The effluent water quality after treatment meets the requirements of the process and product water standard in Table 1 of Water Quality of Industrial Water for Urban Wastewater Recycling (GB/T19923-2005). The concentrated liquid of high pressure reverse osmosis is evaporated by MVR evaporator, and the salt is recovered and comprehensively utilized.

Case 1: Fuling Shale gas field water treatment project

The project is located in Fuling District, Chongqing. The produced water (produced water) has high salt content and complex composition, so it cannot be directly discharged to surface water body. Instead, it needs to be treated by the process of "pretreatment + double membrane treatment + evaporation crystallization" and then discharged.

Processing scale: 2400m³/d

Treatment process: "high pressure reverse osmosis +RO" double membrane process

(Photo: Sinopec Jianghan Design)

Case 2: The Second expansion project of Sulige Gas Field Fracturing Flowback Liquid Water Treatment of Haoxin Ruiyuan Kejing Engineering Co., LTD., Ordos City

Treatment object: fracturing flowback fluid

Processing scale: 600m³ /d

Treatment process: pretreatment + oxidation + hard removal + high pressure reverse osmosis reduction + evaporation

Effluent standard: the produced water shall meet the first-class standard of Integrated Sewage Discharge Standard (GB8978-1996) and the standard of Urban Miscellaneous Water Quality for Reuse of Urban Sewage (GB/T18920-2002) at the same time, and be discharged up to the standard

Case 3: CNPC Chongqing Zhongxian Natural Gas Purification Plant wastewater treatment project

Case 3: CNPC Chongqing Zhongxian Natural Gas Purification Plant wastewater treatment project

Processing scale: 1.3m³ /h

Treatment process: heat exchange + sand filtration + activated carbon + high pressure reverse osmosis

Effluent standard: After treatment, the effluent is used as supplementary water for circulating cooling water system, TDS≤300mg/L, Other water quality indexes should meet the water quality requirements of "water quality of Industrial Water for Urban Sewage Regeneration and Utilization" (GB/T19923-2005) and "Water quality indexes of reclaimed water used for supplemental water of inter-cooling open circulating cooling water system" in "Code for Design of Treatment of Industrial Circulating Cooling Water" (GB50050-2017)

Case 4: Inner Mongolia Yuhongxin Environmental Protection Technology Co., LTD. Gas field fracturing flowback fluid equipment and the whole process treatment project

Processing scale: 800m³/d

Treatment process: pretreatment + advanced oxidation +MBR+ high pressure reverse osmosis +MVR+ (salt separation system)

Effluent standard: effluent discharge index complies with the first level standard of Comprehensive Sewage Discharge Standard (GB8978-1996), while total salt and chloride discharge in sewage meet the standard of Farmland Irrigation Water Quality Standard (GB5084-2005)

With the increase of oil and gas exploration, the number of gas Wells is gradually increasing, and the resulting sewage water is also increasing year by year. The sewage from oil and gas fields has complex components and strong pollution. If it is discharged directly without treatment, it will seriously damage the ecological environment and affect the sustainable exploitation and development of oil and gas fields. How to efficiently treat oil and gas field sewage to achieve the goal of external discharge and reuse, scientific development of oil and gas field sewage treatment, oil and gas field economic benefits and social benefits have a very important significance.

First, the nature of oil and gas field sewage and its harm to the environment

The sewage from oil and gas fields comes from the associated water produced in the process of oil and gas production. In order to obtain qualified oil and gas products, it is necessary to separate the associated water from oil and gas. After separation, the associated water contains a certain amount of crude oil and other impurities. These separated associated water is called oil and gas field sewage.

The sewage from oil and gas fields is directly injected into the formation without effective treatment, which not only has a great influence on the next exploitation, but also has a great harm to the production facilities, and may destroy the formation structure at last.

Second, domestic oil and gas field sewage treatment status

At present, the sewage treatment technologies of oil and gas fields are mainly physical, chemical and biological methods.

Physical method mainly through centrifugation or gravity separation, so that oil impurities, solid suspended matter and minerals in sewage are separated from sewage by centrifugal force or gravity. The method is simple and easy to operate, but the removal degree of harmful substances can not be guaranteed.

Chemical method commonly used chemical reagents, neutralization, chemical process and three methods such as coagulation precipitation chemical treatment method is mainly deal with object for the solubility of water substance and colloid, chemical processing method can effectively improving the quality of sewage treatment, but chemical reagent itself is pollutants, such as improper handling may cause secondary pollution.

Biological treatment is generally achieved through the cultivation of microorganisms that can degrade harmful substances in sewage. At present, the biological treatment generally divided into aerobic biological process, anaerobic biological method and three kinds of aerobic and anaerobic biological method, it can improve quality of wastewater treatment, and won't cause pollution to the environment, but the biological treatment system covers an area of big, long residence time, lower to higher levels of sewage treatment capacity, higher requirements on the processing environment.

The above treatment methods have low efficiency and poor quality of produced water. At present, environmental protection requirements are improved, and more efficient technologies are needed to meet standards for discharge, reuse or zero discharge.

3. Processing technology and advantages of Chengdu Shuote Technology Co., LTD

In the oil and gas field sewage treatment industry, Chengdu Shuote Technology Co., LTD. (hereinafter referred to as "Shuote technology") is the first company in China to adopt high pressure reverse osmosis technology for large-scale engineering application. It has engineering cases of different water quality in many domestic blocks and has quite mature engineering application experience.

According to the different characteristics of various sewage from oil and gas fields, Shuote technology adopts the combination of air flotation, high-density pool, catalytic oxidation and other technologies to pretreat the sewage and remove pollutants such as petroleum, acid and alkali, guanidine gum, calcium and magnesium hardness and organic matter in the water. The pre-treated sewage was reduced concentration and desalted by high pressure reverse osmosis, RO, NF membrane separation processes. The concentrated high-salt wastewater can be recycled by MVR, drying (low-temperature evaporation) and so on.

Main process:

Pretreatment process: air flotation process is used to remove petroleum pollutants in sewage.

The high density precipitation technology was used to remove hardness ions such as calcium and magnesium and other heavy metal ions from water.

Guanidine gum and organic matter in water were removed by catalytic oxidation technology.

Membrane separation process: high pressure reverse osmosis process is used to concentrate sewage to achieve the concentration and reduction of sewage;

RO process can guarantee the further treatment of high pressure reverse osmosis effluent, so that the effluent COD, ammonia nitrogen, salt and other contents are lower.

NF is used for salt separation treatment of sewage to ensure the quality of salt produced by evaporation.

Evaporation process: using MVR process to recycle salt;

The residual mother liquor was treated by drying (evaporation at low temperature).

Aiming at the oil and gas field sewage in different regions and with different water quality, Shuote technology adopts different technology combinations to carry out zero discharge treatment of oil and gas field sewage through "pretreatment + membrane treatment + evaporation", so as to realize reasonable recovery and utilization of water and salt resources.

According to the process design

Process features:

1. Use catalytic oxidation process to oxidize guanidine gum and other macromolecular organic matter in water;

2. Adopt high-density precipitation technology to remove hardness ions such as calcium and magnesium in incoming water;

3. Advanced oxidation technology is adopted to further remove COD in incoming water to ensure that the water produced by high-pressure membrane can meet standards and be discharged externally;

4. Using high pressure reverse osmosis concentration technology to achieve salt concentration;

5. Salt separation can be realized by nanofiltration technology;

6. Adopt MVR evaporation technology to achieve zero discharge of wastewater.

Advantage:

1. Good anti-pollution performance: highly resistant to COD, adapt to water quality fluctuations in a large range, and stable water quality;

2. Good treatment effect: the effluent water quality directly meets the discharge standard listed in Table 1 of "Water Quality of Industrial Water for Urban Sewage Recycling" (GB/T19923-2005);

3. High-doubling reduction of sewage: high-doubling concentration of concentrated brine, reducing the amount of evaporation;

4. High equipment integration: modular equipment, easy to move and process combination;

5. Low power of equipment: low operating power of a single set of equipment, suitable for mobile power supply of wellsite;

6. Zero emission: the whole process system can ensure the final salt quality and achieve zero emission.

Extraction of lithium resources in oil and gas fields:

There are lithium, potassium, boron, bromine and other mineral resources in the water of oil and gas fields. It is found that the content of lithium, potassium, boron, bromine and other mineral resources in the water of many oil and gas fields in China is higher than the lowest industrial grade, which has potential resource utilization value. Survey and assessment project from shale gas resources in sichuan province, according to final results acceptance meeting for five years, the project found that, more than 40 trillion cubic meters of shale gas geology resources of sichuan province technical recoverable resources of about 9 trillion cubic meters, economic recoverable resources of about 5 trillion cubic meters, and some parts of the lithium content is extremely high, to carry out the technology of extracting lithium from oil and gas field water application has great economic value.

Iv. Cases of shuotec Oil and gas field sewage treatment self-built station and comprehensive utilization

Shuote technology has built two water treatment stations in Zigong Jiuda and Suining Botong to provide supporting services for the whole process of oil and gas field water treatment from "pretreatment + concentration and reduction + resource recovery (first-class industrial product, applied in chlor-alkali chemical industry)", striving to become a leading comprehensive service provider of sewage treatment in the oil and gas field.

Suining Botong Technology Co., LTD. Industrial sewage treatment plant

The treatment plant is located in Longping Street, Suining Economic and Technological Development Zone. The eia approval was obtained in 2021 (then the EIA Letter [2021] No. 28). The first-phase treatment scale is 400m³/d, mainly dealing with sewage from atmospheric mine fields around the project, including drilling wastewater, gas field water, completion sewage (fracturing and gas test flowback fluid), etc. The quality of the produced water reaches grade A of Discharge Standard of Pollutants from Urban Sewage Treatment Plant (GB18918 -- 2002), and the chloride reaches grade A of Discharge Standard of Pollutants from Water of Sichuan Province (DB51/190-93).

Zigong Jiuda 500,000 m3 / year shale gas field water treatment plant

The treatment plant is located in the factory of Dengguan Branch of Jiuda Group, Dengguan Town, Yantan District, Zigong City, Sichuan Province. The plant treats the produced water from the gas field produced in the production process of shale gas mining area and uses it back to the standard. The total daily water treatment scale of shale gas field in the treatment plant is 1500m³/d. This project adopts pretreatment + membrane concentration and evaporation concentration processing technology.

The effluent water quality after treatment meets the requirements of the process and product water standard in Table 1 of Water Quality of Industrial Water for Urban Wastewater Recycling (GB/T19923-2005). The concentrated liquid of high pressure reverse osmosis is evaporated by MVR evaporator, and the salt is recovered and comprehensively utilized.

Case 1: Fuling Shale gas field water treatment project

The project is located in Fuling District, Chongqing. The produced water (produced water) has high salt content and complex composition, so it cannot be directly discharged to surface water body. Instead, it needs to be treated by the process of "pretreatment + double membrane treatment + evaporation crystallization" and then discharged.

Processing scale: 2400m³/d

Treatment process: "high pressure reverse osmosis +RO" double membrane process

(Photo: Sinopec Jianghan Design)

Case 2: The Second expansion project of Sulige Gas Field Fracturing Flowback Liquid Water Treatment of Haoxin Ruiyuan Kejing Engineering Co., LTD., Ordos City

Treatment object: fracturing flowback fluid

Processing scale: 600m³ /d

Treatment process: pretreatment + oxidation + hard removal + high pressure reverse osmosis reduction + evaporation

Effluent standard: the produced water shall meet the first-class standard of Integrated Sewage Discharge Standard (GB8978-1996) and the standard of Urban Miscellaneous Water Quality for Reuse of Urban Sewage (GB/T18920-2002) at the same time, and be discharged up to the standard

Case 3: CNPC Chongqing Zhongxian Natural Gas Purification Plant wastewater treatment project

Case 3: CNPC Chongqing Zhongxian Natural Gas Purification Plant wastewater treatment projectProcessing scale: 1.3m³ /h

Treatment process: heat exchange + sand filtration + activated carbon + high pressure reverse osmosis

Effluent standard: After treatment, the effluent is used as supplementary water for circulating cooling water system, TDS≤300mg/L, Other water quality indexes should meet the water quality requirements of "water quality of Industrial Water for Urban Sewage Regeneration and Utilization" (GB/T19923-2005) and "Water quality indexes of reclaimed water used for supplemental water of inter-cooling open circulating cooling water system" in "Code for Design of Treatment of Industrial Circulating Cooling Water" (GB50050-2017)

Case 4: Inner Mongolia Yuhongxin Environmental Protection Technology Co., LTD. Gas field fracturing flowback fluid equipment and the whole process treatment project

Processing scale: 800m³/d

Treatment process: pretreatment + advanced oxidation +MBR+ high pressure reverse osmosis +MVR+ (salt separation system)

Effluent standard: effluent discharge index complies with the first level standard of Comprehensive Sewage Discharge Standard (GB8978-1996), while total salt and chloride discharge in sewage meet the standard of Farmland Irrigation Water Quality Standard (GB5084-2005)

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115

All rights reserved Sichuan ICP No. 12019139 Sichuan Public Network Security No. 44030502001115